14.3.2. Welding start condition - Exclusive setting for GB2/GZ4

14.3.2. Welding start condition - Exclusive setting for GB2/GZ4

(1) Slowdown adjustment: [ 0] % (Range: -10 ~ 10)

Set the offset of the basic speed with which wire is fed until the arc is generated.

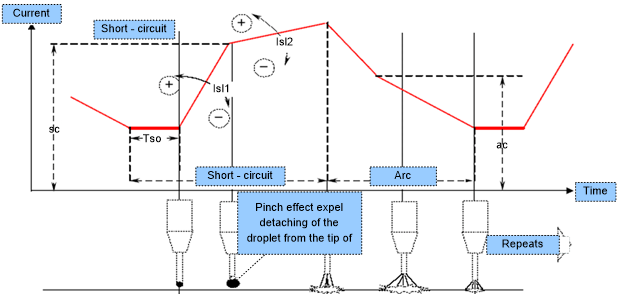

(2) Short-circuit initial time control (Tso): [ 0] (Range: -3 ~ 3)

Set for inhibiting the current from increasing after the wire contacts the welding pool.

When this value gets lower, shock will decrease and spatter will increase and the arc maintainability will get degraded.

If the value gets larger, shock will increase and the arc maintainability will get enhanced.

(3) Short-circuit current refraction value control (Isc): [ 0] (Range: -3 ~ 3)

Set for the adjustment of the current value that connects the slope 1 and sloe.

When this value gets lower (-), spatter will decrease and the arc maintainability will get degraded and sound will get softer. If the value gets larger (+), the arc maintainability will get enhanced and spatter will increase.

(4) Short-circuit current incline 1 control (Isl1): [ 0] (Range: -7 ~ 7)

When this value gets lower (-), arc will get softer and spatter will decrease. If the value gets larger (+), the arc maintainability will get enhanced in high speed welding and spatter will be agglomerated as time passes by.

(5) Short-circuit current incline 2 control (Isl2): [ 0] (Range: -7 ~ 7)

When this value gets lower (-), spatter will decrease, and shock will increase when contacting the welding pool. If the value gets larger (+), the arc stability will get enhanced in high speed welding and more spatters will be created.

(6) Arc current refraction value adjustment (Iac): [ 0] (Range: -3 ~ 3)

Set the refractive current adjustment value to be applied when arc is generated. With the help of this value, amount of spatter will be inhibited at the moment when arc is generated, and the arc length at the moment when arc is generated again will be decided.

(7) Stick prevention time adjustment (Tsp): [ 0] (Range: -3 ~ 3)

Set the stick prevention time.

(8) Hot current control (Ihot): [ 0] (Range: -3 ~ 3)

Set the value of high current to be applied when welding gets started.

(9) Hot voltage control (Vhot): [ 0] (Range: -10 ~ 10)

Set the value of high voltage to be applied when welding gets started. It will decide the arc length.

Figure 14.3 Precision waveform control parameter