4. RESTART

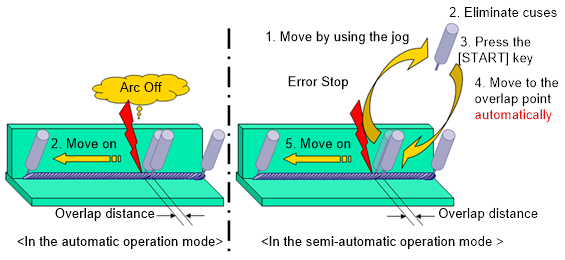

Welding may stop in the middle of it being performed, due to some reasons, such as arc off, welding current and voltage limit exceeded, gas press lowered, wire shortage and errors with coolant. In this case, if welding is resumed at the stopped point, there could be some areas without welding. The restart function is for performing overlapping to compensate for the section where welding is not performed.

In the section for setting the conditions for restart, users can set a restart method when needed to start up welding again after welding stops due to some specific reasons, such as arc off. With this function, in some cases, welding can be started up again automatically without taking separate measures when welding stops. In other cases, when the restart process is initiated after removing the causes of the stoppage, the welder will start welding after moving backward for a certain distance along the welding path first. As a result, there could be an area where welding is overlapped near the area where welding stopped earlier due to errors. Considering that, this function will help prevent an area from being left unwelded when welding is started up again following its stoppage.

The restart function is executed according to the setting adjusted in the welding sub-condition box.

When welding stops from numerous causes, such as arc shutdown, limit breach, lowering gas pressure, insufficient wire, and coolant error, the following methods can be used to restart.

Figure 4.1 Example of restart function (Semi-auto)

l Disable

For setting the welder to prevent overlapping. When errors such as arc shutdown, limit breach, lowering gas pressure, insufficient wire, and coolant error occur, the welding and robot frame will stop. After removing the cause and clicking [Start], the robot will recommence welding from its stopping position without overlapping the welding.

l Ignore

For setting to ignore errors. When the setting is enabled, the robot will continue to move after the welding stops. In other words, even when the arc is turned off or the limit is exceeded, the robot will ignore the situation and move on. This is to be applied only in a case in which the robot needs to be started up again after welding stops as the arc is turned off or the limit is exceeded.

l Semi-auto

For setting to allow the user to carry out overlapping. If the arc is turned off, or if the limit is exceeded, or if the gas pressure is lowered, or if wire runs short or if there is an error with coolant, welding will stop and the main body of the robot will stop also. When the user presses the [Start] key after taking care of the causes of problems, the welder will perform overlapping according to the method set in the restart section of the welding auxiliary condition, before carrying out the main welding work

At this stage, if the user moves the robot to other position by operating the jog and presses the [Start] key, the robot will move to the overlap welding position immediately and carry out welding.

Caution

When pressing the step advance/retreat key during robot transit, the restart info will be cleared and overlapping will not be executed. Always use the jog operation for movement.

l Auto

For setting to allow overlapping to be carried out automatically. This setting is to be applied only in a case in which welding stops because arc is turned off. If arc is turned off while welding is being carried out, the robot will not stop. Instead, it will carry out overlap welding according to the method set in the restart section of the welding auxiliary condition, before carrying out the main welding work. However, if arc is turned off again while welding is being carried out in the overlap welding area, the robot will start welding again at that position immediately.

Refer to [14.5 Welding Auxiliary Condition – Retry, Restart] for more details about how to handle individual cases.