3. RETRY

In some cases at the initial stage of welding, there may be no arc due to impurities attached near the welding start point of the base metal. The retry function enables consecutive operation without having the robot stop by automatically reattempting arc ignition upon failure.

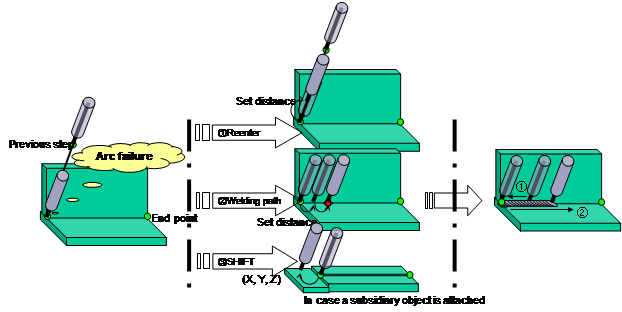

As shown in Figure 3-1, if arc fails to be created, retries, such as “reenter”, “weld path” and “shift”, will be carried out. In case of “weld path” and “shift”, the position for generating arc may vary depending on the amount of movement. Once arc is created, the welder moves back to the welding start point first before carrying out welding. In case of “reenter”, retry to create arc will be made at the position where the arc failed to be created before. Retry is automatically executed according to the retry condition set under the welding sub-condition.

(1) Reenter

The robot retreats from the welding start point towards the torch approach direction by the retreat movement amount, and then makes the reentry. The welding condition used is applied with the original welding condition.

(2) Weld path

The welding restarts after moving from the welding start point towards the welding proceeding direction by the welding path amount. The welding condition applied upon retry is applied with the welding condition of the retry condition number set under the welding sub-condition. Setting the retry condition number to 0 triggers arc ignition attempt under the same condition as the main condition. When the arc ignites normally, the robot returns to the welding start point with the set speed. After returning to the welding start point, the robot starts welding based on the main welding condition.

(3) Shift

The welding restarts after moving from the welding start point by the shift movement amount. The welding condition applied upon retry is applied with the welding condition of the retry condition number set under the welding sub-condition. Setting the retry condition number to 0 triggers arc ignition attempt under the same condition as the main condition. When the arc ignites normally, the robot returns to the welding start point with the set speed. After returning to the welding start point, the robot starts welding based on the main welding condition.

The retry function is set under the retry group of the welding sub-condition. Detailed criteria include “Count”, “Retry condition”, “Operating mode”, “Speed”, “Retract time”, “Retract speed”, “Reentr./Path Dist. “, and “Shift Distance”. To edit the welding sub-condition, click [Quick Open] key under the ARCON command and click [F1: Aux. cnd] to enter the welding sub-condition box. Refer to [14.5 Welding Auxiliary Condition – Retry, Restart] for more details about the setting items.

Welding start point

Figure 3.1 Sequence of retry function

Figure 3.1 Sequence of retry function