14.4. Welding end condition – entering from welding start condition

14.4. Welding end condition – entering from welding start condition

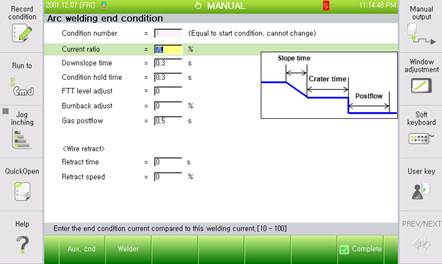

While the arc welding is set as digital, if the [F2: End cnd] key on the welding start condition dialogue box is pressed, the welding end condition editing screen will be displayed as shown below.

Figure 14.4 welding end condition dialog box (Example of digital GB2/GZ4)

After changing an item of the welding end condition, if the [ESC] key is pressed, the screen will move to the welding start condition dialogue box without saving the changed content. If the [F7: Complete] key is pressed, the changed content will be saved and the screen will move to the welding start condition dialogue box.

The ‘FTT level adjust’ of the end condition can be used only for GB2/GZ4, while other items can be commonly used for welders.

The contents of individual items are as shown below.

(1) Condition number: [ 1] (Range: cannot change)

Display the welding start condition number. In case of the digital arc welding function, the end condition number and the start condition number are managed together as one. Accordingly, in order to change the end condition number, the start condition number needs to be changed. In the end condition screen, checking is allowed only, while changing is not.

(2) Current ratio: [ 70] % (Range: 10 ~ 100)

Set output current in crater processing. Set the value in % compared with the main condition (The current value of the start condition).

(3) Down Slope time (Crate Time): [ 0.10] sec (Range : 0.0 ~ 10.0)

Set the time for processing the current change between the main condition and the end condition as a slope.

Figure 14.5 DownSlope time and crate time chart

(4) End condition time: [ 1] sec (Range : 0.1 ~ 10.0)

Set the time for maintaining the output value as set in the ‘current ratio’ item of the welding end condition.

(5) Burnback adjustment: [ 0] % (Range: -20 ~ 20)

Set for processing Burnback.

(6) Gas postflow: [ 0.10] second (Range: 0.3 ~ 10.0)

Set the time for emitting the shied gas continuously even after arc is turned off.

(7) FTT level adjustment (Can be set only for GB2/GZ4): [ 0] (Range: -50 ~ 50)

Set the Fine tip treatment adjustment value. Through this value, the amount of wire agglomerated at the wire tip, after welding, can be adjusted.