7.6.7. Coordinate system calibration for OLP

7.6.7. Coordinate system calibration for OLP

OLP (Off-Line Programming) is used to minimize additional teaching at real sites by planning them in a simulation. The program prepared by using OLP can be downloaded as it can theoretically replace the actual work. However, in real work spaces, there could be various errors, such as errors related to accuracy of the robot, the installed position accuracy of the robot, and the installed position accuracy of a workpiece. These errors are the reasons that the program prepared in OLP cannot be applied to the actual sites.

Accordingly, there is a need to calibrate between the position calculated in OLP and the actual work position. The function to perform this calibration is “OLP installation error calibration”. This function can correct the OLP installation errors by creating the difference relationship between two coordinate systems and teaching the robot at the same location as the reference program of the CAD used in the OLP.

In the calibration method provided by this function, the user coordinate is used. The user teaches the robot program by using the user coordinate.

If the reference program created in the OLP and user-created programs are inputted, the difference value between the two programs is added to the previously designated user coordinate.

As a result, the program’s work position taught based on the user coordinate will be calibrated to match the actual workpiece position.

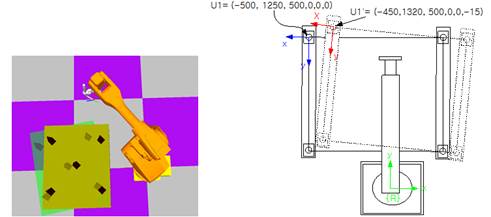

As shown in the following figure, the workpiece 1 was placed in the U1 position in OLP. However, if it is actually installed in the U1’ position, there will be differences between the two coordinates, -50mm, 70mm, and 0mm in the X, Y, and Z directions, respectively. Also, there will be differences of 0 deg, 0 deg and, -15 deg in the Rx, Ry, and Rz directions, respectively. This function will calibrate the error in installation by calculating U1’ instead of U1.

Figure 7.102 Example of coordinate calibration for OLP

Hi5a controller supports 10 user coordinates. Accordingly, it is possible to set each user coordinate for each workpiece to calibrate the error in installation.

For more details, refer to 『“Coordinate calibration for OLP” Function Manual』.