2.6.2. Example of machining (deburring and chamfering)

2.6.2. Example of machining (deburring and chamfering)

The following is an example of machining (deburring or chamfering) using the force control. Develop the program for deburring or chamfering with the following example.

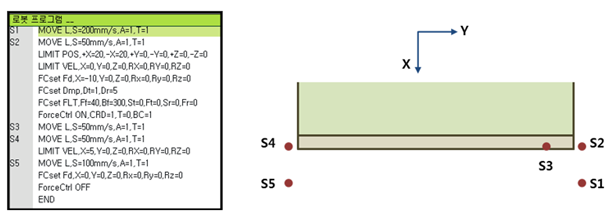

Figure 2.10 Example program of machining (deburring and chamfering)

Table 2‑2 Example program of machining (deburring and chamfering)

Robot motion | § Move from S1 to the starting point of the work, S2. § Then, turn on the force control but set the LIMIT VEL § Move to S3 without the force control. § Move S4 with the force control by setting the LIMIT VEL. § Move S5 with the force control off by changing the LIMIT VEL to 0. Then, turn off the function to exit the program. |

Max. operation area (LIMIT POS) | § Set the force control working range from the position of S2 to start the force control based on the robot coordinate system. X=-20–20 [mm] § Only allows X-directional force control. |

Max. operation speed (LIMIT VEL) | § Based on the robot coordinate system (given that Force Ctrl ON is CRD=1): § S2, S3: 0 [mm/s] è Force control OFF in all directions § S4: X=5 [mm/s] è X-directional force control ON § S5: 0 [mm/s] è Force control OFF in all directions |

Size of force to control (FCset Fd) | § X=-10 [N]: A 10 N contact force is maintained in the -X direction. § Set the size of the force considering the degree of machining. |

Robot conditions for force control (FCset Dmp, FLT) | § Dt=1: X-directional 1-step flexibility control § FLT: Flexible control with Ff and Bf values Smaller value results in smoother motion but might cause delay |

ForceCtrl ON, CRD=1, T=0, BC=1 | Execution of force control § CRD=1: Force control operation based on the robot coordinate system (1) § T=0: Force control tool data No. 0 is used. § BC=1: Initializes the force sensor data to start the force control. |

ForceCtrl OFF | End of force control |