8.7.3. Setting STITCH function parameters

8.7.3. Setting STITCH function parameters

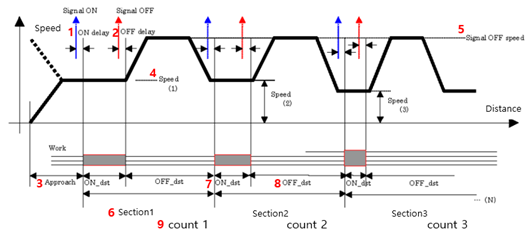

Figure 8.26 Profile in line with the stitch welding process

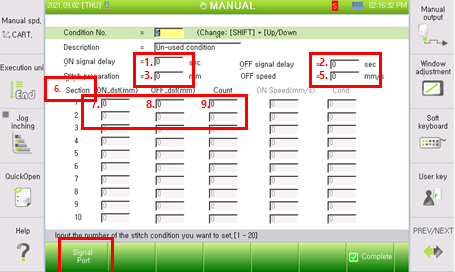

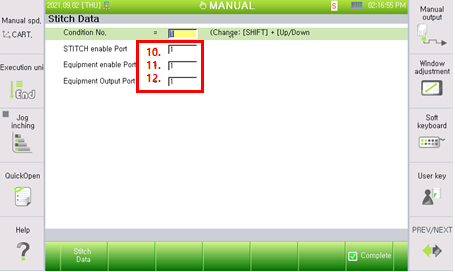

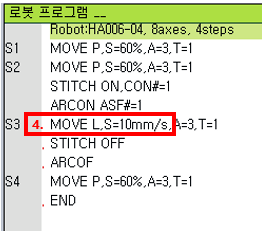

Figure 8.26 displays a screen you can access by pressing the “Quick Open” button in the “STITCH” command, while Figure 8.27 presents the screen where you can enter with the “Signal Port (F1)” button in Figure 8.26. Moreover, Figure 8.28 shows the screen of a job program for which the command is used. The parameters of the number marked in red in Figures 8.26–8.28 can be described below.

Condition no.: Select with the “Shift” + direction keys.

Description: Can be inputted using the soft keyboard

1. On signal delay time

à Time for the welding signal to be turned on in advance

2. Off signal delay time

à Time for the welding signal to be turned off in advance

3. STITCH preparation distance

à Section length for entering the “On” section speed before stitching

4. ON speed: Welding speed at the welding section

5. OFF speed: Welding speed at the nonwelding section

6. Section: Stitch welding condition

Ex.: If the stitch welding under the section 1 condition progresses as much as the count, the stitch welding corresponding to the section 2 condition will progress.

7. ON_dst: Welding section length

8. OFF_dst: Nonwelding section distance

9. Count: Stitch welding count

Stitch Enable / Equipment Enable / Equipment Output

à Stitch welding will progress during playback only when “1” is inputted for the three parameters.

* Only after all data are inputted in “7. ON_dst,” “8. OFF_dst,” and “9. Count” will it be possible to input the conditions for section 2.

*Inputting “1all” in “10. STITCH Enable Port,” “11. Equipment Enable Port,” and “12. Equipment Output Port” is required for stitch welding to be performed during playback. Otherwise, only the stitch operation will proceed (Welding X).

*4. ON speed: In the stitch section, the speed of the welding (ON) section should be set as the step speed.

Figure8.27 Stitch welding parameter setting no. 1

Figure8.28 Stitch welding parameter setting no. 2

Figure 8.29 Stitch welding parameter setting no. 3