8.6. LVS LVS-based welding condition change function

8.6. LVS LVS-based welding condition change function

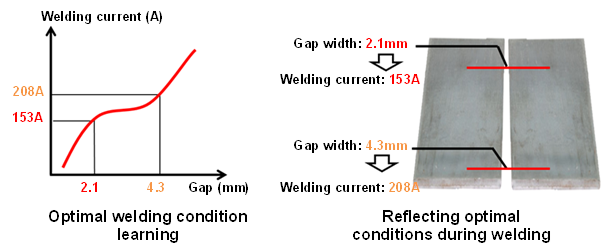

This function is used to change the welding current and voltage based on the width of the gap measured using LVS. This will optimize the welding condition based on the gap measured while tracking the welding path by LVS. If the workpiece has deformation due to heat, causing the gap to be uneven, the welding condition can be changed according to the variation of the gap to ensure stable quality in welding.

Figure 8.19 LVS-based welding condition change function

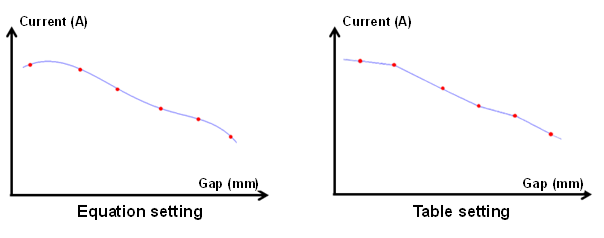

In order to seek the optimal welding condition, preset conditions will be used. Relevant user interface will be provided.

Figure 8.20 User interface for setting the optimal condition (Left: Table setting method. Right: Equation setting method

In order to set the change condition in the LVS-based welding condition change function, it is necessary to acquire preset conditions. Acquiring preset conditions means finding the welding conditions proper for the gap in the environment for which the function will be applied, ahead of applying the conditions. According to the gap, acquire the previous conditions and input into the provided user interface after performing the actual welding. When using this function, the users will be provided with the table setting method and the equation setting method. For the table setting method, 2 ~ 6 preset conditions need to be entered to change the current welding condition to a welding condition proper for the entered gap by implementing the linear interpolation between the entered preset conditions. For equation setting method, 2 ~ 6 preset conditions need to be entered to change the current welding condition to a welding condition proper for the entered gap by implementing the curved interpolation between the entered preset conditions.

Figure 8.21 Condition change depending on the setting methods