8.5. LVS(Laser Vision Sensor) welding path tracking and detection function

8.5. LVS(Laser Vision Sensor) welding path tracking and detection function

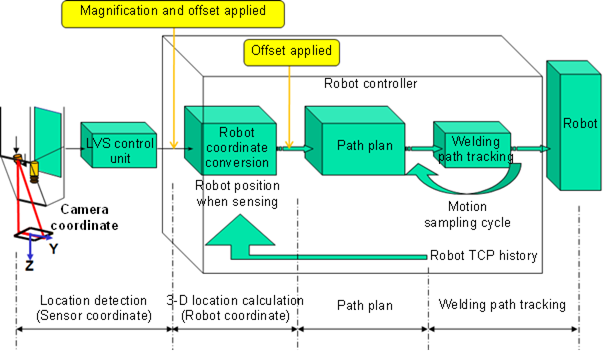

This function will help recognize the welding path by using the LVS to detect and track the changed welding path in a given environment in order to provide stable quality in welding. LVS is installed near the torch mounted on the robot to recognize the detection target and send the relevant information to the robot. The robot moves the tool tip to the recognized location by using the received information. When the location of the welding workpiece is changed, making it impossible to perform welding at the existing teaching point, the robot will move the tool tip to the welding start point to ensure the starting of welding from the correct position.

In addition, while welding is in progress, LVS will keep recognizing the welding path and send this information to the robot, making it possible for the robot to perform accurate welding along the welding path. This function can help secure stable welding quality even when the location of the welding workpiece changes frequently or the welding path is not even.

Figure 8.17 LVS welding path tracking data flow

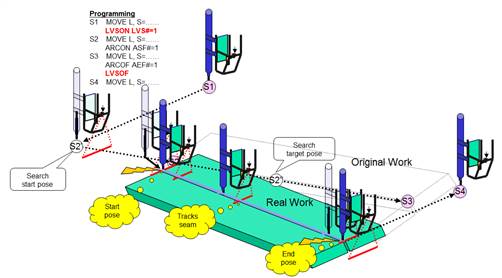

The LVS welding path tracking and detection can be performed by using the LVSON command. For the environment setting of the function and specific details, it is necessary to refer to “LVS welding path tracking and detection function manual.” As this function requires an engineer’s assistance, it is necessary to contact the manufacturer.

Figure 8.18 LVS welding path tracking data flow