4.3.5.1. SD3X3Y (Medium-Size) and SD3L3Y (Large-Size) 6-Axisintegrated Drive Unit

4.3.5.1. SD3X3Y (Medium-Size) and SD3L3Y (Large-Size) 6-Axisintegrated Drive Unit

The drive unit plays a role of amplifying power by sending current to each motor according to the current command from the servo board. The 6 axis all-in-one drive unit can operate 6 motors at the same time, and the following table shows its components.

Diode module converter is integrated with servo amp, and the 3-phase current from the electric module is rectified with a diode module; converted to DC; and stored in the smoothing capacitor. When the speed of the robot is reduced, power generated from a motor is consumed through a transistor and resistance. The diode module converter is constructed as shown below.

Table 4‑36 The Components of SD3X3Y (Medium-Size) and SD3L3Y (Large-Size) 6-Axis integrated Drive Unit)

Component | Function | |

BD552 (Logic Board) | Separation of the PWM signal from the servo board into upper and lower IPM drive signals, and execution of error processing | |

BD551 (IPM Board) | Gate Drive Module | Generation of IPM gate signals |

Gate Power Module | Generation of gate power | |

Current Detection Unit | Detection of the current flowing into the motor | |

BD561 (Converter Board) | Rectifier Unit | Generation of DC power circuit provided from the AC input main power. |

Regenerative Control | Drive of IGBT if PN voltage increases | |

Error Detection Unit | The detection of overvoltage, overheated regenerative resistance, and bibliographic data input errors | |

Other Components | Heat Sink | Emits heat generated by power modules |

IPM | Switching Device | |

Capacitor | DC power smoothing | |

Regenerative IGBT | Execution of regenerative control | |

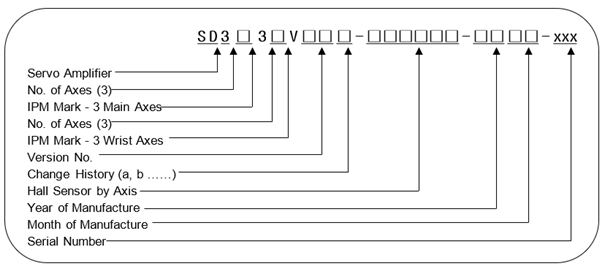

n Type number system of medium(Lagre) 6-axis integrated drive unit

Table 4‑37 Type code of medium(Large) 6-axis integrated drive unit

Classification | Mark of Type |

Servo Drive | SD |

Table 4‑38 Specifications of medium(Large) 6-axis integrated drive unit

Item | Classification | Application | ||

IPM Capa. | 3X | 3Y | HS180, HH300, HX400 | 6-Axis integrated Type |

4X | 2Y | HC2502B2D, HC2503B2D | ||

3L | 3Y | HC3303B1DA, HC3303B2DA | ||

Year | 00 ~ 99 | Year of Manufacture: 2000 ~ 2099 | ||

Month | 01 ~ 12 | Month of Manufacture: 1 ~ 12 | ||

Serial No. | 001 ~ 999 | No. of units manufactured per month: 1 ~ 999 | ||

Table 4‑39 Medium(Large) Size IPM Capacity

Medium Size(Large Size) | L | (IPM Rated Current) 150A, (Hall Sensor Rated Current) 4V/75A |

X | (IPM Rated Current) 100A, (Hall Sensor Rated Current) 4V/50A | |

Y | (IPM Rated Current) 75A, (Hall Sensor Rated Current) 4V/50A | |

Z | (IPM Rated Current) 50A, (Hall Sensor Rated Current) 4V/25A |

Table 4‑40 Hall sensor code for medium(Large) IPM

AMP Model | Hall Sensor Mark (Spec.) | Full-Scale Current (Im) | AMP Feedback Constant (Iv) |

Medium (Large) servo drive unit | 0 (4V/75A) | 140.62Apeak | PM150CL1B060(150A) |

1 (4V/50A) | 93.75Apeak | PM100CL1B060(100A) PM75CL1B060(75A) PM50CL1B060(50A) | |

2 (4V/25A) | 46.87Apeak | ||

3 (4V/15A) | 28.12Apeak | ||

4 (4V/10A) | 18.75Apeak | ||

5 (4V/ 5A) | 9.37Apeak |

Table 4‑41Specifications of medium(large) 6-axis regenerative IGBT

Regenerative IGBT | L | 150A, Regenerative Resistance: 2Ω 2000W 2EA Applicable |

Table 4‑42 Specifications of medium(large) 6-axis integrated electrolytic condenser

Chemical Condenser | 2C | 3300uF 2EA |

Caution: As the drive unit varies depending on the robot, so please check out the form of it in replacing it. |

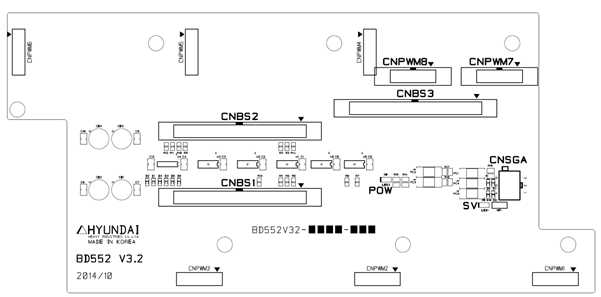

Figure 4.55 BD552 Component Layout

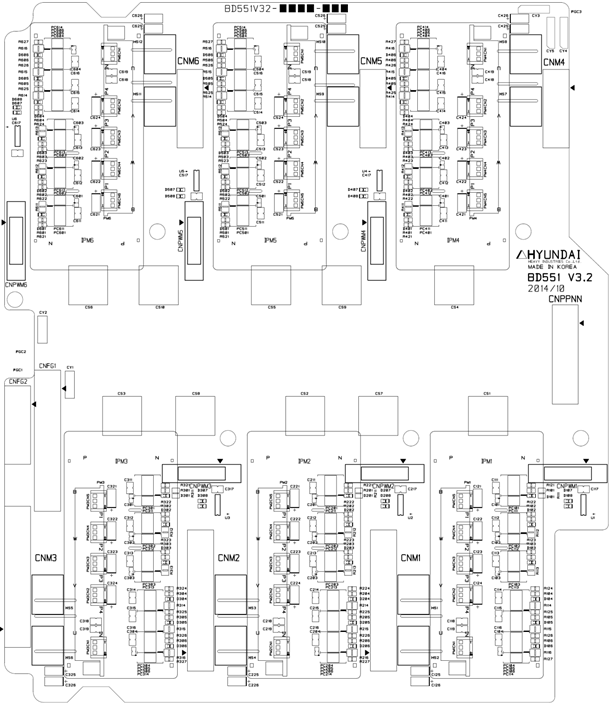

Figure 4.56 BD551 Component Layout

Table 4‑43 BD552 Connector

Name | Use | External Device Connection |

CNBS1, 2, 3 | PWM Signal and Error Signal | Servo Board(BD544) CNBS1,2,3 |

CNSGA | /PWMON, SVERR, BRAKE | Sequence Board (BD530) CNSGA |

CNPWM 1~6 | PWM Signal and Error Signal | Servo Amp BD551 CNPWM1~6 |

CNPWM 7~8 | Additional Axis PWM Signal and Error Signal | Option Board(BD554) CNPWM |

Table 4‑44 BD551 Connector

Name | Use | External Device Connection |

CNM 1~6 | Motor Connection | CMC1, CMC2 |

CNPWM 1~6 | PWM signal and error signal | Servo Amp BD552 CNPWM1~6 |

CNPPNN | Power for motor drive | Drive Power Unit (BD561) CNPN1 |

CNFG1 | The frame ground of the Main axis motor | CMC1 |

CNFG2 | The frame ground of the Wrist Axis motor | CMC2 |

Table 4‑45 BD552 LEDs

Name | Color | Status Display |

SV | Yellow | ON if PWM is ON |

POW | Green | OFF if current dip/sag occurs |

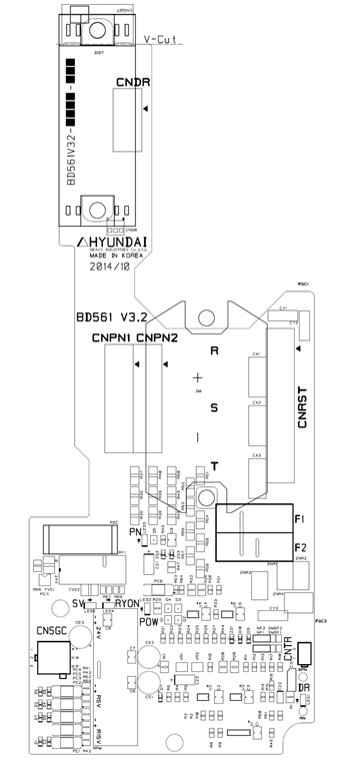

Figure 4.57 BD561 Component Layout

Table 4‑46 Description of BD561 connector

Name | Use | External Device Connection |

CNRST | 3-Phase Power Input | Electrical Module CNRST |

CNSGC | /PWMON, OV, FLT, FB | Sequence Board(BD530) CNSGC |

CNDR | Regenerative Power Output | Regenerative Resistance |

CNTR | Detection of Overheated Regenerative Resistance | Thermal Sensor of Regenerative Resistance |

CNPN1 | For Supply of PN Power | 6-Axis Servo Amp CNPPNN, Additional Axis CNPN |

CNPN2 | For Supply of PN Power | Additional Axis Servo Amp |

Table 4‑47 Description of BD561 LED

Name | Color | Status Display |

SV | Yellow | ON if PWN is ON |

POW | Green | OFF if control voltage sag occurs |

DR | Red | ON if regenerative power discharge operates |

PN | Red | ON if PN voltage is over 42V |

RYON | Red | OFF if PN power discharge operates |