7.3.1. Tool data

7.3.1. Tool data

Set the distance and angle of the robot’s R1 axis flange in reference to TCP (Tool Center Point) and register the center of gravity and inertia. The user can manually enter the items.

Another method is to use the automatic constant setting function for the tool distance. The center of gravity and inertia can be registered using the load estimate function.

The tool distance and angle must be correctly set before the teaching process. This is because the path during straight line or arc interpolation is generated based on TCP.

Hi5 controller is controlled based on the robot dynamics. The weight, inertia and center of the tool must be set accurately for the robot to operate quickly and safely. When this value is incorrect, it can cause serious problems to the performance and life of the robot.

Especially if you are using the tool change function, you must allocate a separate tool number not just for the condition in which the tool is separated but also for the information of each tool to enter and use the tool information for the tool change function.

Also for the handling of heavy objects, each tool number must be allocated for the attach/detach condition of the object for use.

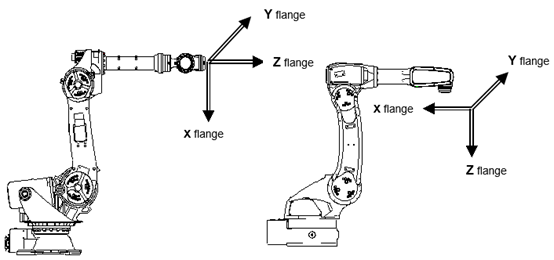

Tool length is the length by each direction in the flange coordinate system shown as follows.

(1) Distance in X axis : Xt

(2) Distance in Y axis : Yt

(3) Distance in Z axis : Zt

Figure 7.27 Flange coordinate system by robot type

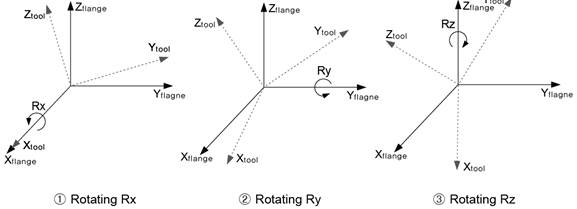

Tool angle is the amount of position change in each direction in the flange coordinate system.

(1) Angle in X axis : Rx

(2) Angle in Y axis : Ry

(3) Angle in Z axis : Rz

Figure 7.28 Tool angle

Therefore, the tool distance and angle is set based on the flange coordinate. Tool distance is the set between the center of the flange coordinate and TCP.

The tool position is the rotated values of X, Y and Z axis direction in reference to the tool flange coordinate according to the set tool angle.

Rxyz = Rot(z,Rz)Rot(y,Ry)Rot(x,Rx)

Rxyz is the tool position rotation matrix based on tool flange

Rot(z,Rz) is the rotation matrix that shifted by Rz to the Z axis direction of flange coordinate

Rot(y,Ry) is the rotation matrix that shifted by Ry to the Y axis direction of flange coordinate

Rot(x,Rx) is the rotation matrix that shifted by Rx to the X axis direction of flange coordinate.

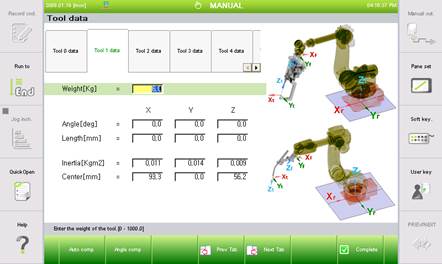

Figure 7.29 Tool data setting screen

n Weight (Kg) : Weight of tool

n Angle(deg)

You can use the tool angle, automatic constant setting or 『[F2]: Angle comp』function.

n Length (mm)

You can use the tool distance, automatic constant setting or 『[F1]: Auto comp』function.

n Inertia (Kgm2)

You can use the tool inertia load calculation function for the tool coordinate.

n Center (mm)

You can use the weight center location and load calculation function of the tool based on the flange center.

l When moving the cursor and entering the data for the angle or distance item, it may prompt you the message saying “Consult the engineer” in the guide frame. Use the 『[F1]: Auto comp』 or 『[F2]: Angle comp』keys. Please refer to the following detail for automatic calibration and angle calibration.

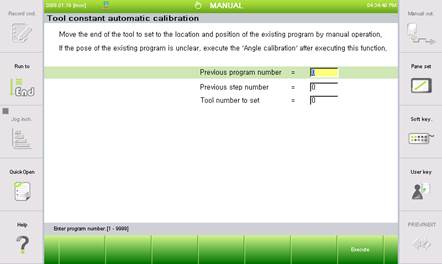

l Automatic calibration

① If you locate new tool for setting to the step location where existing step was, and then the distance and the angle for the new tool is calculated.

Figure 7.30 Tool constant automatic calibration screen

n Previous program number

Enter the program number taught before the tool change.

n Previous step number

Enter the step number to execute tool constant auto calibration.

n Tool number to set: Enter the tool number to newly set.

② Through the automatic calibration function, you can easily generate the tool data and also use the existing program as it is.

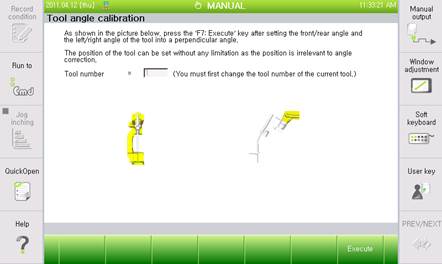

l Angle calibration

This sets the tool angle and calibration.

Figure 7.31 Tool angle calibration screen