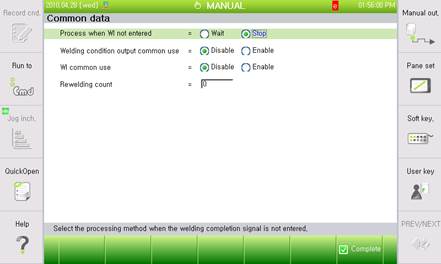

3.4.1. Common data

3.4.1. Common data

Setting data that is commonly applied regardless of spot welding sequence will be executed from this screen.

(1) Process when WI not entered

This selects the process for errors that occur in the event that WI is not entered after the set welding complete (WI) wait time. Robot operation should be waited or stopped. If waited, robot operation should be waited until the welding complete signal is received.

(2) Welding condition output common use

In the event that multiple spot welders are used, the welding condition signal will generally be set separately for each welder, but if applying one common welding condition signal for multiple spot welders, this item shall be set as [Enable].

(3) WI common use

In the event that multiple spot welders are used, the WI signal will be generally set separately for each welder, but if applying one common WI signal for multiple spot welders, this item shall be set as [Enable].

(4) Rewelding count

Re-welding should be executed in the event that WI is not received after the set welding complete (WI) wait time. A maximum number of re-welds can be assigned (up to 3 times), and if WI is not received after trying as the maximum number of re-welds, an error should be issued and ‘Process in the event of no WI input’ should follow.