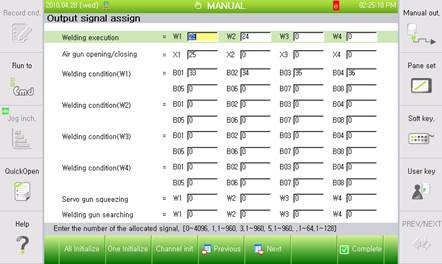

3.6. Output signalassign

3.6. Output signalassign

Output signal assign related to spot welding will be executed from this screen so that the signal status will be delivered to outside.

(1) Welding execution

This is used to output welding commands to the welder when the SPOT command is executed.

(2) Air gun opening/closing

This is used to control air gun opening/closing.

(3) Welding condition

This assigns the signal number, which will output the welding condition when the SPOT command is executed. When assigning a welding condition signal that is up to 8 bits between B01~B08, maximum of 256 conditions can be used.

When more than 2 welding guns are used, the setting should be done to each welding line.

(4) Servo gun squeezing

This is the signal that will be turned on when squeeze is carried out by the SPOT command, and turned off when the opening process is initiated.

(5) Welding Gun Searching

This is the signal that will be turned on when gun search is carried out by the GUNSEA, IGUNSEA, or EGUNSEA command, and turned off when the opening process is initiated.

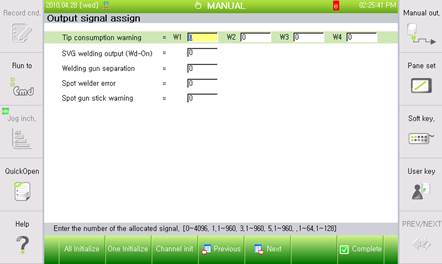

(6) Tip consumption warning

This is used to cut a signal when the consumption detected by gun search exceeds the tip exchange consumption.

(7) SVG welding output (Wd-On)

This is used to display a signal when “Servo-gun spot welding output type” is set as Wd-On in the spot-gun common parameter setting menu.

(8) Welding gun disconnection

This displays that the welding gun is separated. If the gun type is servo-gun, it displays the message when all electric signals (encoder power, motor current) are turned OFF after the disconnection process.

(9) Spot welder error

This is used to display spot welder errors when they are received.

(10) Spot gun sticking warning

This is used to display spot-gun stick when it occurs.