4. Arc Welder Setting

4.1. Arc welder setting

This function for editing the characteristics of welders allows the use of various welders together with the arc welding robot. The following describes steps to access the welder setting screen.

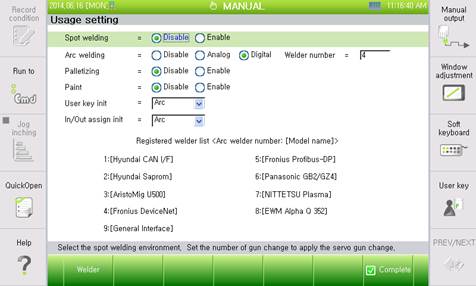

First of all, when a welder needs to be used, the user can set it through the ‘Welder Number’ item by selecting the 『[F2]: System』 → 『5: Initialize』 → 『3: Usage Setting』. When the user selects 『[F1]: Welder』, then the screen for editing the conditions of the relevant welder will be displayed.

Figure 4.1 Usage setting dialog box

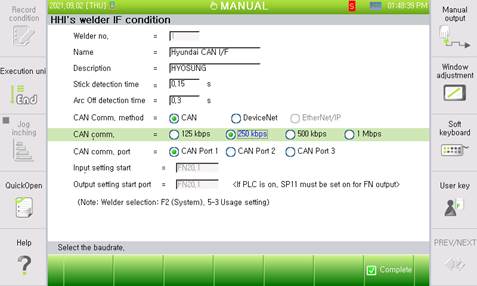

Figure 4.2 Welder setting dialog box (when BD574+CAN communication is used)

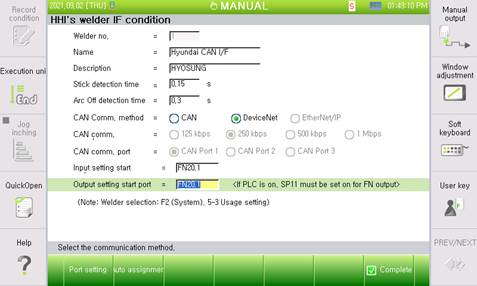

Figure 4.3 Welder setting dialog box (when BD574+DeviceNet communication is used)

As individual welder condition screens provide editing functions relevant to specific welders, the editing items will vary depending on welders. The following items are the common items that can be edited on the condition screens of welders.

The items that can be edited commonly are as shown below.

(1) Number

Display current setting welding number. Through the relevant item, the currently selected welder and its number can be checked. Changing the information is possible only through the ‘usage setting’ screen.

(2) Model type

Record the model name of welder. Basically, the model name of welder supported by our company is written.

(3) Description

Record the welder description. Basically, the name of welder maker is written.

(4) Stick detection time: [0.2] sec (Range: 0.1 ~ 10.0)

Once welding is completed, wire stick will be inspected during the set time.

(5) ARC OFF detection time: [ 0.6] sec (Range: 0.0 ~ 10.0)

Set the reference time for the arc off that could occur in the middle of arc welding. If the arc stays turned off for longer than a specific duration, the state will be recognized as arc off. If the value is small, arc ignition failure would occur frequently. However, if the set value is too large, the time duration in which robot movement and wire inching continue even after the arc is off will increase, causing the robot movement distance and the wire projection length to increase.

4.2. HRWI characteristic file editing

4.3. Panasonic welder characteristic file editing

4.4. ESAB/Fronius/EWM welder characteristic file editing