4.8.4. Average load rate diagnosis

4.8.4. Average load rate diagnosis

This is to display the average load rate of the motor torque applied for each axis during the robot operation. The calculation of the average load rate is to be made only during the normal operation without the robot suffering any servo errors or emergency stops, excluding the excessive torque that will be generated during the abrupt stop.

The average load rate is calculated based on the motor torque I/lr, and the calculation takes place by using the buffer fixed inside the robot controller, so, the average load rate renewal time will vary depending on the characteristics of the work program of the robot. When it comes to each axis, the average value is calculated by taking into consideration the moving time of each axis, so the torque during the stop of the robot operation will not be taken into the calculation of the average load rate.

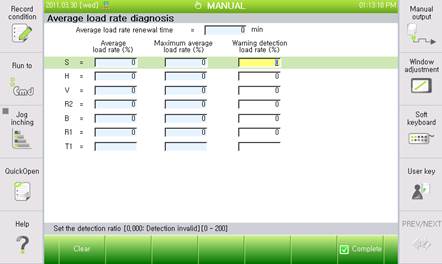

Select『[F1]: Service』 → 『7: System diagnosis』 → 『9: Average load rate diagnosis』.

(1) Average load rate renewal time [min]

This is the time of the robot operation by calculating the average load rate. In those cases where servo errors or emergency stops occur, their load factors will not be taken into the calculation.

(2) Average load rate [%]

This is the average load rate (l/lr) of the motor of each axis generated during the average load rate renewal time. The average load rate will start to be displayed when the targeted butter is filled in the robot controller, while ‘0’ for it is displayed before that. The time required for the buffer to be filled will vary depending on the characteristics of the work of the robot.

(3) Maximum average load rate

This is the maximum value of the average load rate generated during the robot operation. When the controller power is turned off, or 『[F1]: Clear』is selected, the value can be measured again. However, the data will be displayed ‘0’ during the average load rate renewal time.

(4) Warning detection load factor

This needs to be set to generate a warning for the user if the average load rate of each axis exceeds the general usage level. If it is ‘0’, detection will not occur, so it is required to set the value. When an warning occurs, the “W0142 %s axis) Average load rate error during task.” notification will be displayed on the teach pendant, while the set output will be generated according to the average load rate diagnosis of 『[F2]: System』→『2: Control parameter』→『2: Input/output signal setting 』→『4: Output signal assignment』. Even when the warning occurs, the robot will continue the work without stopping.

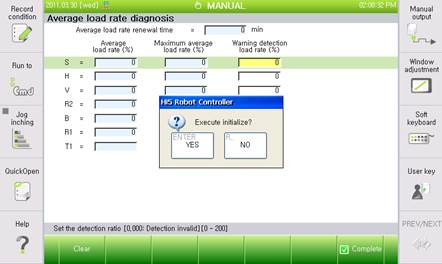

(5) 『[F1]: Clear』

Measuring will start again. Even in this situation, waiting for the buffer to be filled is still required

l When『[F1]: Clear』is selected, the guide frame will display the following message.

l When the [Yes] key is selected, all the average load rates saved up to now will be deleted and initialization will take place.