4.4. Teaching by applying conveyor desynchronization

4.4. Teaching by applying conveyor desynchronization

When it comes to a program that runs to the final step while being synchronized with the conveyor, the position of the robot may vary depending on the conveyor speed. In particular, if the conveyor moves fast, it will take a long time to shift from the final step of the current cycle to the 1st step of the next cycle, which will cause the position of the final step of the next cycle to move downstream further. Such phenomenon will repeat itself at every cycle with accumulative effect, causing the robot to be inoperable finally due to the errors with the soft limit of the robot.

In order to avoid the situation, it is needed to desynchronize the conveyor ahead of the final step to make the robot carry out the next cycle at the same position for each cycle.

n Teaching example 1

The following shows a program example that applies conveyor desynchronization.

Step 1 SensorSync Sensor=1,Sync=1 WaitSensor Sensor=1,Sync=0,Pos=500 Step 2 Step 3 Step 4 SensorSync Sensor=1,Sync=0

Step 5 END | → Conveyor synchronized playback on → Conveyor interlock wait

→ Conveyor synchronized playback off

|

If the conveyor synchronized playback off command is recorded for Step 4, the robot will move to the position where Step 5 is recorded, without being synchronized with the conveyor at Step 5. In other words, the robot will stop at the same position (where Step 5 is recorded first) always regardless of the conveyor, ensuring that it will take the same time constantly to move to the first step of the next cycle

n Teaching example 2

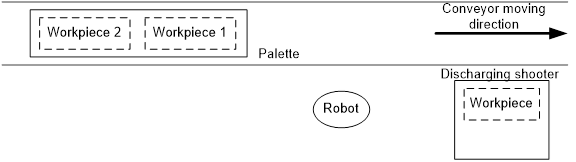

Let’s learn about how to perform teaching for a system that can move workpieces one by one to the discharging shooter when two workpieces are placed on one pallet and transported on a conveyor as shown below.

(1) Take Workpiece 1 on the palette while being synchronized with the conveyor.

(2) Place Workpiece 1 on the discharging shooter. At this moment, the conveyor should be unsynchronized as the discharging shooter is not on the conveyor.

(3) Take Workpiece 2 on the palette while being synchronized with the conveyor.

(4) Place Workpiece 2 on the discharging shooter. At this moment, the conveyor should be unsynchronized as the discharging shooter is not on the conveyor.

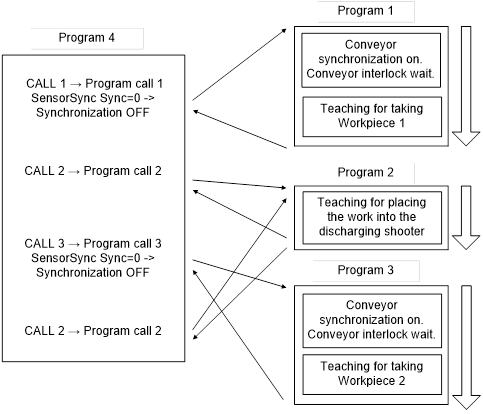

If it is needed to perform this operation, it would be convenient to split the works into blocks. The following figure shows the example of the teaching for such operation.

For this system, 4 programs need to be prepared and applied.

Program 1 is for carrying out teaching for Workpiece 1, and Program 2 is for carrying out teaching for transporting the workpiece to the discharging shooter, and Program 3 is for carrying out teaching for taking Workpiece 2. Then, the three programs are to be called by Program 4. However, the conveyor synchronized playback should be turned off before Program 2 is called.