4.1. Conveyor synchronized operationsequence

4.1. Conveyor synchronized operationsequence

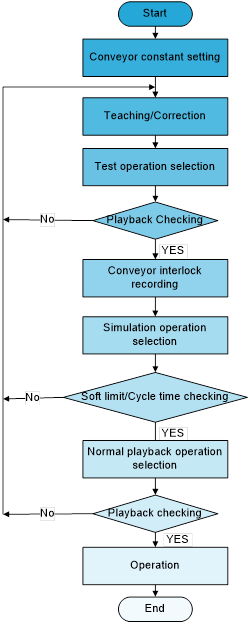

The conveyor synchronization operation takes place in a sequence that is shown below, which includes synchronization parameter setting, teaching and correction, playback for checking, and normal playback.

n Conveyor parameter setting

This step is required at the initial stage after installing the conveyor system. As this step will decide the level of position errors of all types of synchronized playback operations, the setting should be handled carefully.

n Teaching and correction

Once the conveyor parameter setting is completed, it is required to operate the conveyor to make the workpiece pass through the limit switch and enter the working range. When the workpiece reaches the desired position, it is required to stop the conveyor and carry out teaching and correction.

n Playback for checking

Once the teaching and correction processes are completed, it is required to carry out playback for checking, depending on the conveyor operation type, in the order of the test mode, the simulation mode and the normal mode. Of those processes, the playbacks for checking for the test mode and the simulation mode are not essential, so the playbacks for them can be performed when necessary based on the user’s judgment in line with the system environment.

n Normal playback

When the playback for checking is completed and no problem is found, it is required to set the conveyor at the normal operation mode and execute playback for the actually moving conveyor.