2.3.4. Common coordinate setting

2.3.4. Common coordinate setting

The common coordinate setting is only possible when the accurate position of the cooperation robot tool end is known. At this time, the robot calibration must be done. If there is not a 3-dimensional positioner available, the Hi5 controller provides the auto constant setting function that calibrates the axis constant and the tool length (『[F2]: System』 → 『6: Auto Constant Setting』→ 『1: Optimize Axis Constant And Tool Length』). If a 3-dimensional positioner is available, correct calibration based on kinematics will be possible. Use 『9: Calibrate Robots And Tools.

For more details please refer to the『Hi5 Controller operation manual』. Set the common coordinate after setting the most delicate automatic constant.

The common coordinate setting is explained in an environment involving two robots, Robot 1 and Robot 2.

n Teaching method

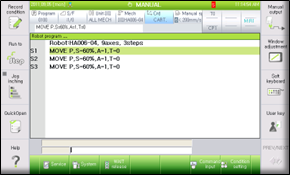

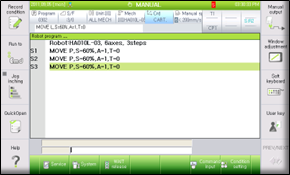

① Select the program to record in the applicable controller for Robot 1 and 2.

Ex) When registering the cooperation coordinate system programs of both robots 1 and 2 to 100

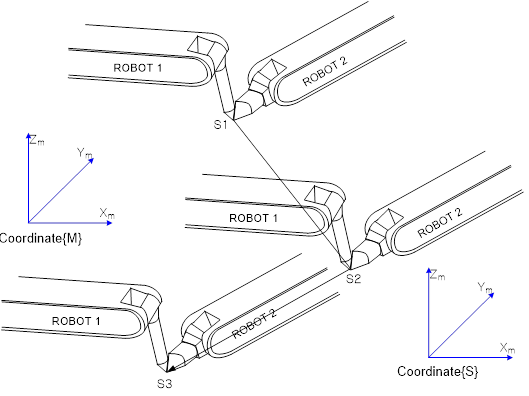

② By using each jog of Robot 1 and 2, record the 3 points to step 1, 2 and 3 in order to create a triangle, as large as possible.

Robot1 Robot2

At this time the record position is to be recorded at the same location in the space, and, when it comes to the tool number, the tool that was used when setting the common coordinate needs to be used, independently the interpolation method and the speed.

Caution

l For the tool data for common coordinate setting, enter the accurate tool specification or calculate the tool data through automatic constant setting.

l It is recommended that the robot position of each point is recorded in the same way.

l Records should be kept by carrying out the teaching in a way that the 3 set points create a big triangle as much as possible. If the distance among the points is close, or if the 3 points are forming a straight line, an error will occur.

l If the common coordinate is not set, the manual cooperation jog operation or the cooperation replay will be made impossible.

l It is recommendable to carry out the work in a full scale after checking, through the cooperation jog operation, whether the common coordinate setting among the cooperation robots are carried out correctly.

Figure 2.5 Teaching method of common coordinate setting

③ Execute the cooperation coordinate setting for each robot (robot 1 and 2).

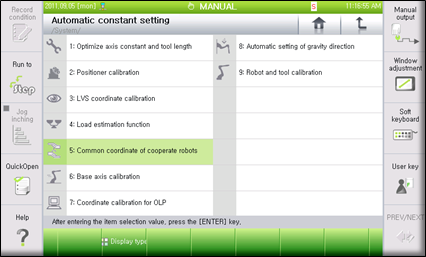

④ Select 『[F2]: System』 → 『6: Automatic constant setting』 in manual mode.

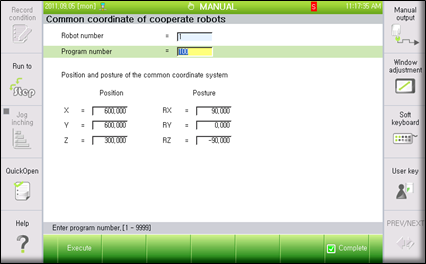

⑤ Select 『5: Common coordinate of cooperate robots』.

※ The meaning of the above parameter is as follows.

n Robot number: The robot number set in cooperation control parameter.

n Program number: The program number for cooperation robot coordinate registration

⑥ Press the 『[F1]: Execute』 key. The results will be displayed in the screen through position and position of the common coordinate from robot base. Relative positions are in X, Y, Z and relative positions are in Rx, Ry, Rz.

⑦ Press the 『[F7]: Complete』 key to complete the setting.