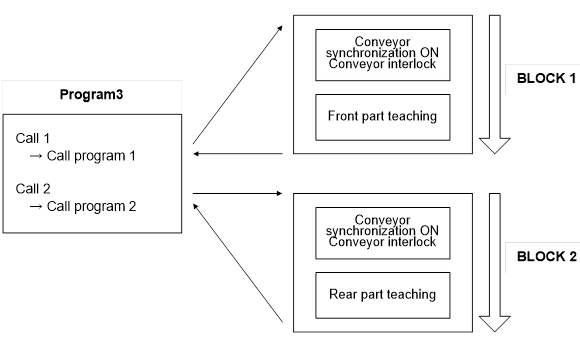

4.3.2. Program preparation by block division

4.3.2. Program preparation by block division

Program preparation by block division is done according to the following procedure.

n Block 1 teaching

(1) Check whether the conveyor data is cleared.

(2) Move the conveyor to operate the limit switch by the workpiece. When the teaching part of the workpiece reaches the front side of the robot, the conveyor stops. Conveyor pulse counter and register value are calculated to respond to the current location of the workpiece.

(3) Workpiece teaching is done for the current location and use the previous/next step to check the teaching results.

(4) Select conveyor operation from 『[F2]: System』 → 『4: Application parameter』 → 『4: Conveyor synchronization』 → 『1: Environment setting』 to <Test>. When END command is executed for the program in normal mode, the conveyor data is cleared. And because the signal input is required during conveyor operation, select the test mode to avoid this situation.

(5) While keeping the workpiece in the current location, press the run button to check the playback.

(6) CNVYSYNC and WAITCNVY commands are recorded in step 0.

n Block 2 teaching

(1) Select and playback the final step of program 1.

(2) Move the conveyor until the teaching part of the 2nd block reaches the front side of the robot, and stop the conveyor.

(3) After selecting the manual mode, select program 2.

(4) Execute the teaching as block 1.