4.4. Teach with conveyor synchronization canceled

4.4. Teach with conveyor synchronization canceled

The operating program by conveyor synchronization up to the final step shows different robot location at the final step depending on the conveyor speed. Especially if the conveyor is fast, it takes longer to operate from final step to the 1st step of the next cycle, and the location at the final step of the next cycle moves further downstream. As this phenomenon is repeated and accumulated for each cycle, the robot finally generates a soft limit error to stop the operation.

To avoid this, the conveyor synchronization is canceled in front of the final step so that the robot can always execute the next cycle from the same location.

n Teaching example 1

The following shows an example of a program using the conveyor synchronization cancel function.

Step 1 CNVYSYNC 1 → Conveyor synchronization playback ON WAITCNVY SYNC=0,D=500 → Conveyor interlock standby Step 2 Step 3 Step 4 CNVYSYNC 0 → Conveyor synchronization playback OFF Step 5 END

|

In step 4, the conveyor synchronization playback OFF command is recorded and in step 5, the robot does not synchronize with the conveyor and just moves to the location recorded on step 5. That is, the robot will always stop at a certain location (Location where step 5 is initially recorded) irrelevant from the conveyor and the moving time to the 1st step of the next cycle is always consistent.

n Teaching example 2

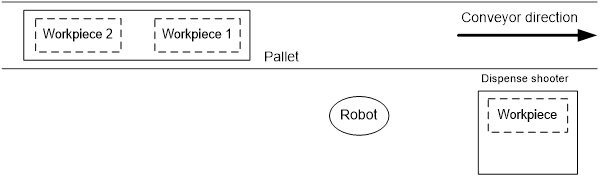

As shown below, let’s learn about the teaching method for the system where 2 workpieces move on the pallet on top of the conveyor and the robot moves one workpiece to the dispense shooter respectively.

(1) Synchronize the robot to the conveyer to hold workpiece 1 on the pallet.

(2) Place workpiece 1 on the dispense shooter. At this time, the dispense shooter is not on the conveyor and the conveyor synchronization is canceled.

(3) Synchronize the robot to the conveyor to hold workpiece 2 on the pallet.

(4) Place the workpiece 2 on the dispense shooter. At this time, the dispense shooter is not on the conveyor and the conveyor synchronization is canceled.

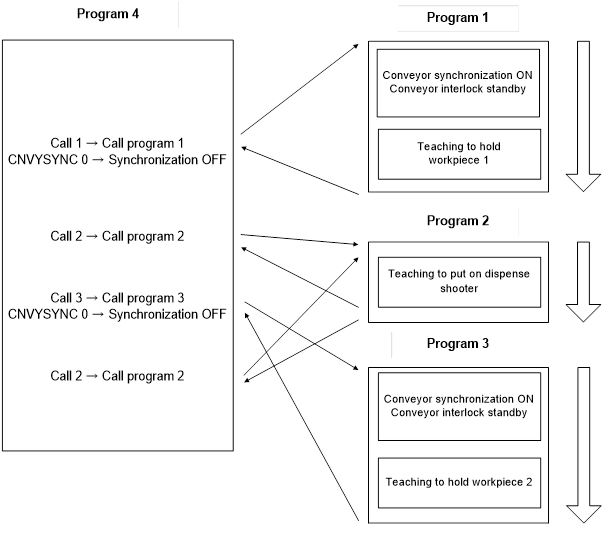

(5) When executing this operation, it is convenient to use the block division described above and the teaching example is as follows.

(6) In this system, 4 programs have to be prepared.

(7) Program 1 is taught to hold workpiece 1. Program 2 is taught to move the workpiece to the dispense shooter. Program 3 is taught to hold workpiece 2. And then program 4 is taught to call programs 1, 2 and 3. But before calling program 2, the conveyor synchronization playback must be turned OFF.