4.1. Conveyor synchronization operation procedure

4.1. Conveyor synchronization operation procedure

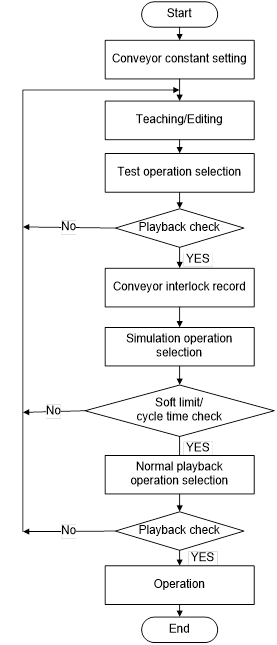

Conveyor synchronization operation is done in the order of conveyor parameter setting, teaching and editing, check playback and normal playback according to the following flowchart.

n Conveyor parameter setting

As the initially required stage after installing the conveyor system, this decides the location error level of all synchronized playback work and must be set carefully.

n Teaching and editing

After the conveyor parameter setting is completed, operate the conveyor so that the workpiece can pass through the limit switch to enter the work zone. When the workpiece reaches the desired location, stop the conveyor and teach and edit the process.

n Playback check

When the teaching and editing is completed, playback the process according to the conveyor operation type in the order of test, simulation and normal mode. Here, the test and simulation operating mode are not mandatory processes and they can be appropriately judged by the user depending on the user environment.

n Normal playback

When the playback check is completed, and the issues are all cleared, select the normal mode to operate the conveyor to playback the conveyor for actual flow.