13.1. Function summary

13.1. Function summary

When teaching of an arc welding operation program needs to be performed, not only the welding related conditions, such as voltage and current, but also details of the arc welding functions such as weaving and retry/overlap and characteristics of the welder, should be set. Additionally, not only in the arc welding, but also in general cases that would used a robot, it may be required, in some cases, to check the information (such as coordinates and pose) of the position not only of the steps set through teaching, but also of the auxiliary points. The arc welding condition file and the position information of the steps and auxiliary points are managed inside the controller in the form of a file, meaning that it would not be easy to edit them. That is why a function to help edit those files easily and fast is provided.

Quick Open is a function that will make it possible to set the arc welding conditions or check and edit the information of the steps and auxiliary points by using a key once without going through inconvenient operation.

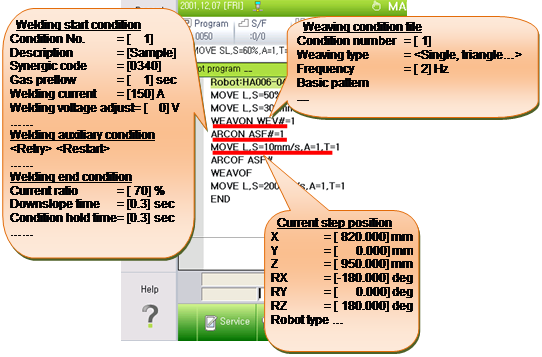

Here, we take the case of editing the welding start condition, as an example. While the cursor is on the ARCON command that is for the Arc On function, if the user presses the [Quick Open] key, the screen will display the content that matches with the number of the condition, among those for starting welding, that is being used by the current command. On this screen, it is possible to check or change the details of the welding start condition. It is also possible to shift to other condition files that are related to the relevant condition file.

As explained above, this function will make it possible to check and change, easily and fast, relevant details of a condition file or a step position in relation to a specific command.

Figure 13.1 Quick open in the robot program

Clicking the [Quick Open] key in certain commands displays relevant files or details on the screen. After saving the changed content in a file, if it is required to end the process, the <Complete> key needs to be pressed. If required to end without saving, the <ESC> key needs to be pressed.

The content displayed when pressing [Quick Open] in each command is as follows.

Command | File, content | Details | Note | |

MOVE | Pose | Current position and command values. X Y Z(mm) Rx Ry Rz(deg) Robot configuration | Can correct the command values | |

CALL | Program to be called | Shift to the program that is targeted for calling |

| |

JMPP | ||||

Assignment statement | Confirm and change variable | Monitor and change relevant variables depending on their types Including V%, V!, V$, P, R, LV%, LV!, LV$, LP, LR, and system variables | ||

ARCON ASF#= (Only for analogue arc welding) | Digital: Digital arc welding condition file

Analogue: Arc welding start condition file

Arc welding auxiliary condition file | Welding initiation condition Condition number, Description, Synergic code, Gas preflow, Current/feed speed, Welding voltage (correction)/Arc length, WCR wait time, Robot delay time, …

Welding auxiliary condition - Retry: Count, Retry condition, Operation mode, Speed, Retract time, Retract speed, Reentr./Path Dist., Shift Distance - Restart: Count, Restart condition, Overlap length, Moving speed, Welding speed

Welding end condition Current ratio, Downslope time, Condition hold time, Gas preflow, …

Welding auxiliary condition (Enter the end condition) - Auto Stick Recovery: Count, Stick recovery condition, Stick recovery time | ||

ARCOF AEF#= | Arc welding end condition file Arc welding auxiliary condition file Arc welding characteristic file | Welding end condition file Condition number, Voltage confirm, Description, Auto stick recovery, Current, Voltage, crater time, gas time

Welding auxiliary condition file Auto stick recovery: Counter, Current, Voltage, Delay time | ||

WEAVON WEV#= | Weaving condition | Weaving condition file Condition number, Weaving type, Frequency, Basic pattern, Forward angle, Moving time, Boundary limit, Timer | ||

REFP | Reference point | Current Pose and command. X Y Z(mm) Rx Ry Rz(deg) Robot configuration | The command can be modified Same as the “Pose” screen | |