5.1.6. R1-Axis Reduction Gear

5.1.6. R1-Axis Reduction Gear

Attention

Do not inject excessive grease. The excessive grease would cause an abnormal operation. |

n Grease Replacement

① Prepare a grease nipple A-PT1/4 and then make the R2, B, R1-Axis 0°degree.

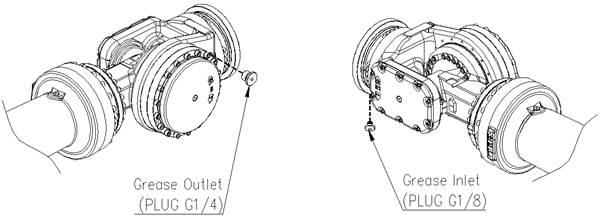

② Remove the grease inlet plug and install grease nipple A-PT1/4.

③ Remove the grease outlet plug.

④ Inject the grease into the grease inlet using a grease gun.

ü Grease type : VIGO GREASE RE0 ü Amount of grease: 1,000 cc(900 g) |

⑤ The grease replacement is complete when new grease appears in the outlet port. The new grease can be distinguished from the old one by color.

⑥ Discharge excessively fueled grease and residual pressure. (Refer to the discharge procedure below.)

⑦ Clean the greased around the outlet and assemble the seal-taped plug into its original state.

n Procedure in discharging excessively fueled grease and residual pressure after grease replacement and injection

① Attach a grease receiver or a hose to the grease outlet to prevent contamination from discharged grease.

② Operate it within a range without surrounding and interference under the following conditions.

A. Operation angle : 60° or more

B. Operation speed : 100%

C. Operation time: 20 minutes or more

③ Wipe the outlet port with a cloth and attach the plug.