4.5. Checking the timing belt

4.5. Checking the timing belt

The driving part of all the axes, except for the S axis, has a timing belt.

For the operating assembly of the timing belt, check the tension of the belt after every 1,500 hours and when there is vibration/noise on the belt. If the tension of the timing belt is not appropriate, it may have a severely negative effect on the performance of the robot.

n Check the timing belt

① Turn off the power.

② Take off the arm pipe cover.

③ Press the center of the timing belt with the given force (F=0.2kgf).

④ Check the pressed length.

⑤ If the pressed length is not appropriate (3.4mm), loosen the motor flange bolt slightly.

⑥ Set the tension of the timing belt.

⑦ Tighten the motor flange bolt.

⑧ Assemble the arm pipe cover.

⑨ Turn on the power.

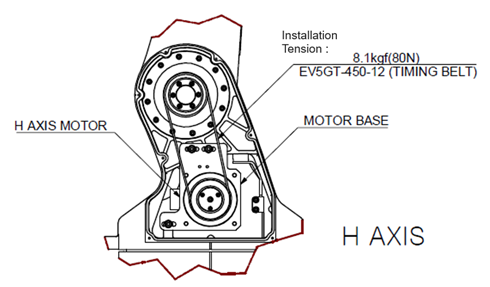

Figure 4.3 Location to check the tension of H axis timing belt [HH007C]

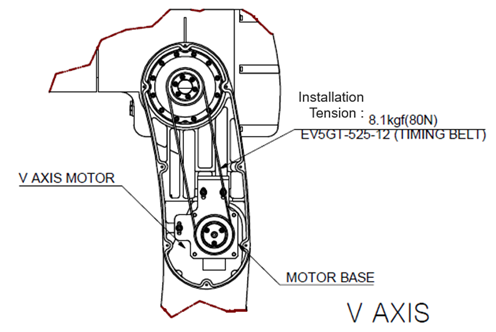

Figure 4.4 Location to check the tension of V axis timing belt [HH007C]

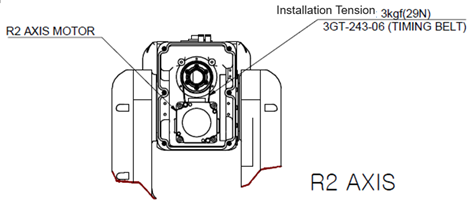

Figure 4.5 Location to check the tension of V axis timing belt [HH007C]

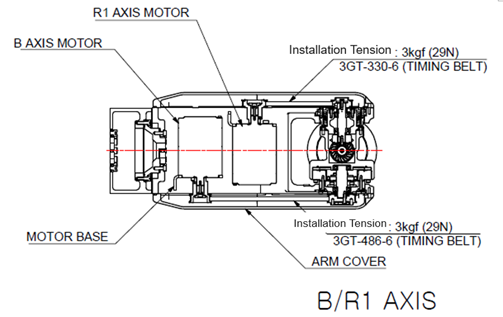

Figure 4.6 Location to check the tension of V axis timing belt [HH007C]