9.2.2. When the pressure of the nitrogen gas container goes below 150bar (Supplement the gas by using a booster)

9.2.2. When the pressure of the nitrogen gas container goes below 150bar (Supplement the gas by using a booster)

(1) Position the H axis of the robot at 90 degrees and cut off the power of the controller.

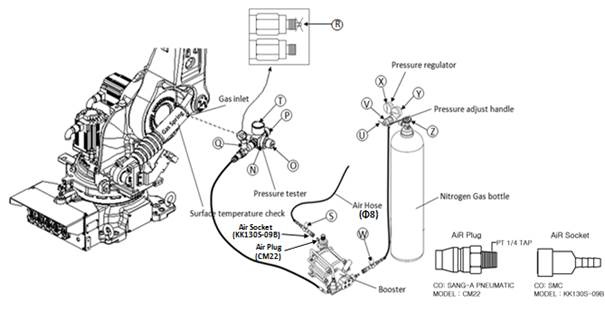

(2) Remove the plug installed in the gas inlet of the spring.

(3) Check the closed state of the bleed valve ⓟ and shutoff valve ⓠ of the pressure tester.

(Turn clockwise to close)

(4) Turn the knob ⓞcounterclockwise to prevent the release pin ⓡ from protruding.

(5) Turn the knob ⓝ of the pressure tester clockwise to completely connect it to the gas inlet.

(6) Check whether the handle ⓤ, shutoff valve ⓦ, knob ⓢ (Knob of the air hose owned by the customer) and the shutoff valve ⓠ are locked.

(7) Connect the connection section screw of the regulator to the nitrogen gas container screw.

(Connect the connection section of the hoses to individual connection inlets.)

Because the specification for the nitrogen gas container screw varies in different countries, you must purchase a regulator that fits the specification of the nitrogen gas container screw.

(8) Gauge ⓧ shows the set gas pressure and gauge ⓨ indicates the pressure of the nitrogen gas container.

(9) Open the knob ⓩ of the nitrogen gas container, and turn the handle ⓤ of the regulator ⓥ to set the gas pressure. (The set gas pressure is specified in Table 9.1 Pressure per temperature.)

(10) Open the shutoff valve ⓦ of the hose connected to the regulator ⓥ and slowly turn the shutoff valve ⓠ, which is to be connected to the pressure tester, counterclockwise until the indicator of the pressure gauge ⓣ matches with the indicator of the gauge ⓧ.

(11) When the knob ⓢ (Knob of the air hose owned by the customer) is opened after the connection section of the air hose is connected to the booster, the booster starts operation.

Charge until the indicator of the pressure gauge ⓣ reaches the set pressure.

While charging is in progress, the minimum air pressure should be above 5bar. When the residual pressure of the nitrogen gas container goes below 30bar, carry out replacement.

(12) If the set pressure is reached, lock the valve ⓠ and open the bleed valve ⓟ to release the residual pressure inside the pressure tester.

(Do not turn the bleed valve ⓟ by more than 360˚.)

(13) Lock the bleed valve ⓟ and slowly turn the knob ⓞclockwise while checking whether the indicator of the pressure gauge ⓣ matches with the set pressure before stopping.

Be careful not to cause damage to the check value mounted to the gas spring by inserting the release pin ⓡ too far.

(14) When the set pressure is exceeded, repeatedly open and close the bleed valve ⓟ slightly to adjust the gas pressure to the desired level.

(15) Turn the knob ⓞ counterclockwise to retract the release pin ⓡ.

(16) If the pressure is checked, open the bleed valve ⓟ to completely release the residual pressure inside the pressure tester.

(17) Lock the knob ⓢ of the air hose and separate it from the booster.

(18) Lock the shutoff valve ⓦ of the hose connected to the regulator and then lock the handle ⓤ.

(19) Close the knob ⓩ of the nitrogen gas container and separate the hose connected to the regulator from the booster, and then open the shutoff valve to completely release the residual pressure inside.

(20) Separate the shutoff connection section from the pressure tester.

(21) Turn the knob ⓝ of the pressure tester counterclockwise to separate it from the gas spring. Install the G1/8 plug to the gas spring.

After charging gas, wait for 30 minutes until the temperature comes back to room temperature, and then use it.

Figure 9.3 Refill the gas into the gas spring of booster

As the shape and name of the gas supplement kit may vary depending on the type, refer to the accompanying manual. To refill or charge using the booster, refer to the manual provided with the kit. |