9.3. Release Gas from the Gas Spring

9.3. Release Gas from the Gas Spring

Releasing of gas from the gas spring will be performed in each of the following cases:

- In the event that the H-axis cannot be placed at 90°because of its nonoperation when you want to remove the gas spring from the robot

- In the event the robot is to be transported by air. (The law mandates that transportation of machinery to which high-pressure equipment is attached should be made after removing its pressure.)

Cautions

When the gas is released rapidly, the colored oil inside the spring may gush out. Wear safety glasses and ensure that discharging takes place slowly. |

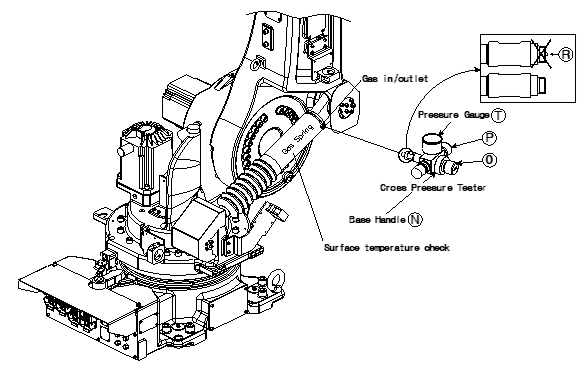

(1) Remove the plug that is installed at the gas inlet of the spring.

(2) Check if the handle Bleed Valve ⓟ is locked (turn clockwise to lock).

(3) Check if the gas release pin, displayed as ⓡ, sticks out. If the release pin is protruding, turn the knob ⓞcounterclockwise to prevent it from protruding.

(4) Turn the base handle ⓝ of the pressure tester in a clockwise direction to connect it to the gas inlet.

(5) Turn the knob ⓞclockwise and stop turning when the indicator of the pressure gauge ⓣ moves. (Do not turn the handle ⓞ excessively to prevent damage to the valve in the gas spring from the release pin ⓡ.)

(6) Turn the gas discharge handle Bleed Valve ⓟ slowly in a counterclockwise direction to discharge gas completely.

Warning! Do not look into the gas inlet hole directly.

(7) Turn the knob ⓞcounterclockwise to retract the release pin ⓡ, and then turn the knob ⓝ of the pressure tester counterclockwise to separate it.

(8) Install the G1/8 plug to the gas spring.

Figure 9.4 Release Gas from the Gas Spring