4.2.1. SPOT command

4.2.1. SPOT command

Execute the spot welding step again in the event that the operation is stopped and executed again while spot welding is not yet completed.

[GUN] LED is illuminated when recording a step using the [Record] key, and SPOT command will be recorded together with MOVE command. (One-touch recording)

To set the panel thickness when the welding step is recorded, it is necessary to bring the fixed tip into contact with the panels through the jog operation. Then, while squeezing the panel manually, it is needed to record the SPOT command through one-touch recording method to set the panel thickness. After the panel thickness is set, it is necessary to bring the fixed tip into contact with the panel through the jog operation. After that, without manual squeeze, it is necessary to record the SPOT command through one-touch record method, the recording will take place by taking into consideration the panel thickness and the corrected position based on the tip consumption.

When the gun type is servo gun, if the SPOT command exists when carrying out [Position correction], the relevant position will be corrected by taking into consideration the tip consumption.

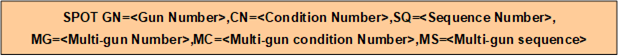

Item | Description |

Gun Number | Designate the welding gun number |

Condition Number | Designate the welding condition |

Sequence Number | Designate the welding sequence |

Multi-gun Number | Designate the multiple gun numbers when carrying out welding with multiple guns at the same time. |

Multi-Gun Condition Number | To be designated because the welding condition varies depending on the guns when carrying out welding with multiple guns at the same time. If not designated, the welding condition of the basic gun will be applied. |

Multi-Gun Sequence Number | To be designated because the welding sequence varies depending on guns when carrying out welding with multiple guns at the same time. If not designated, the welding sequence of the basic gun will be applied. |

Example of usage)

If carrying out spot welding by using servo-guns 5 and 6 simultaneously with 7 and 8 for each welding condition, and 9 and 10 for each welding sequence.

=> SPOT GN=5,CN=7,SQ=9,MG=6,MC=8,MS=10