4.11. SWDfile recovery function

4.11. SWDfile recovery function

The settings related to spot application are saved in the controller’s (ROBOT.SWD) file. When copying the (ROBOT.SWD) file to share welding conditions and sequences with other robots, not only welding conditions and sequences but also other settings will be changed, possibly causing problems such as change of the gun search reference location, gun search status, or squeeze force; etc.

To prevent the problems above, warnings will be generated when the SPOT and GUNSEA commands are executed if copying of the (ROBOT.SWD) file causes any change of the main parameters such as the gun search reference location, squeeze force – current table, etc.

Caution: If the user copies a file to recover the controller initialization settings, it is required to set an exception to the test above. The test will not be performed if the user disables the change test when copying the SWD file by entering 『[F2]: System』 → 『4: Application parameter』 → 『1: Spot welding』 → 『2: Usage environment setting』.

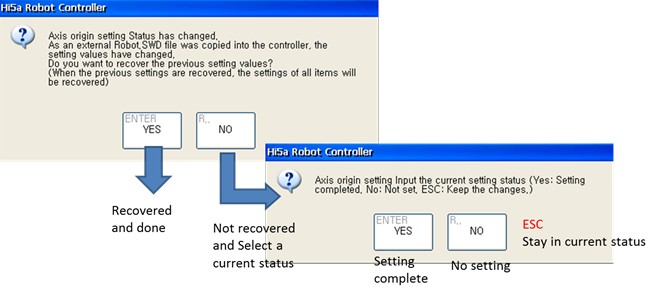

The SWD file recovery function allows the user to initially perform recovery only once when the main parameters are changed due to the copying of the ROBOT.SWD file.

This function can be executed by entering 『[F2]: System』 → 『4: Application parameter』 → 『1: Spot welding』 → 『9: SWD file recovery』.

At this time, if the parameters of the currently selected gun number are changed, the SWD file recovery process will proceed. The point of time for which the recovery will be performed is the time just before the file was changed due to copying. Please note that recovery may be impossible if the data of the previous state is lost due to the repetition of recovery.

This function can be executed using R code. Execution with R code requires permission from the engineer or above.

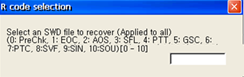

n [R]+[367]: Recovers the designated settings of all guns

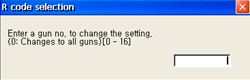

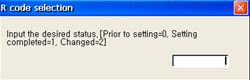

n [R]+[366]: Only the warning output can be removed without changing or recovering the setting status of the designated gun. After inputting the desired number, input the desired setting and the desired status in order.

n Setting number

0 PreChk: Precheck

1 EOC: Encoder offset setting

2 AOS: Axis origin setting

3 SFL: Soft limit setting

4 PTT: Squeeze force – current table tuning

5 GSC: Gun search

6 GBC: Gun arm bending setting

7 PTC: Panel thickness compensation

8 SVF: Servo gun setting confirmation

9 SIN: Input signal setting

10 SOU: Output signal setting