2.3. Step 1.Basic setting

2.3. Step 1.Basic setting

After the pre-check is complete, you can carry out basic setting. Basic setting is a compulsory setting process to set the reference location of the moving tip of the servo gun, move it to the desired location, and apply the desired squeeze force.

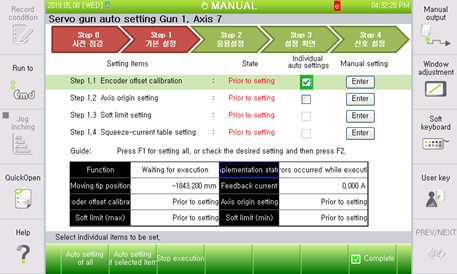

Basic setting consists of four items as shown in the figure below.

(1) Encoder offset compensation

- Normally, the encoder origin should be set where the same location can be mechanically matched when the encoder data is changed following the replacement of the servo gun motor for example. In the case of the servo gun, the setting should be performed while the moving tip is mechanically at the maximum open location.

- For manual setting, refer to “Encoder offset compensation” in “Manual setting.”

(2) Axis origin setting

- Normally, the servo gun axis origin should be set, while a new tip is attached to both the moving and fixed electrodes, at the location where the two tips touch each other. As most of the operation of the servo gun is performed based on the axis origin, it is very important to set it.

- For manual setting, refer to “Axis origin setting” in “Manual setting.”

(3) Soft limit setting

- Normally, the servo gun soft limit should be set to “Minimum” while the moving tip is opened at the maximum level, and at the same time, it should be set to “Maximum” at the closest location in which all tips are removed.

- For manual setting, refer to “Soft limit setting” in “Manual setting.”

(4) Squeeze force – current table setting

- To squeeze the various servo guns installed on the robot with the desired squeeze force, it is necessary to make the current applied to the servo gun correspond to the generated squeeze force. For this, we provide a servo gun squeeze force – current table, and it is necessary to tune the table to the servo gun.

- To use this function, five representative values should be selected from the squeeze force range that will be used. The tuning of the servo gun squeeze force – current table is a process of finding the current table that matches with the five representative values of squeeze force. This table can be changed according to the posture of the servo gun. Therefore, it is necessary to carry out tuning both for the case in which the moving tip is in the direction of gravity and for the case in which it is in the opposite direction of gravity. That way, squeeze can be carried out with high accuracy with the servo gun at various postures.

- For more details, refer to the “Servo gun squeeze force – current table tuning” section.

The basic setting can be carried out both in the autosetting and manual setting modes.

(1) Autosetting: The servo gun will automatically move to the designated location and perform the designated setting.

- Items for autosetting

n Encoder offset compensation

n Axis origin setting

n Soft limit setting

- The squeeze force – current table setting cannot be automatically carried out because it requires user intervention such as the installation of squeeze force gauge.

(2) Manual setting: The user performs the operation to move the servo gun to the designated location and performs the function designated in the specific setting screen.