2.1.1. Set Tool No. and Gun-type

2.1.1. Set Tool No. and Gun-type

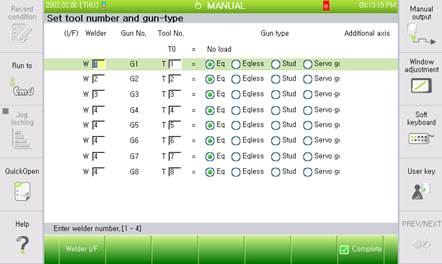

Set the tool number and the gun type that corresponds to the spot-gun number. This provides support for setting various welding guns in a way that they can be used for individual welders and tool numbers. As welding methods vary according to the gun type, the tool number and the gun type should be set correctly.

The “Welder” section is for designating the welder connected to the relevant gun number. When the relevant gun performs welding, signals will be inputted and outputted through the ports that match the relevant welder setting. Multiple guns can be shared and used through the servo tool change function.

A “tool” is an object that is to be combined with the R1 axis front end of the robot, and the robot must know the tool’s information. “Tool No.” means the tool number to be matched with the relevant gun number. In the tool number, the load estimation and tool data should already be inputted. In general, each gun is different in type, so choose a unique tool number for each gun number. As the “G5”–“G7” stationary-type guns will not be combined with the R1 axis front end, they can be arbitrarily set. Please note that playback will be impossible, when the work teaching is performed, if the gun number of the “Spot” command and the tool number of the “Move” command, which are to be used for welding, do not match.

In the “Gun type” section, select a relevant one from the four gun types. If the type is a servo gun, input the information of the additional axis assigned to the gun together. When it comes to the information, it is required to note that when using the servo tool change function, the same additional axis may be assigned to multiple guns.

In the figure above, “G1”–“G4” guns need to be set in a way that you can use the servo tool change function by enabling the four welding guns to use the same welder (W1). As the “G5”–“G7” guns will be set as stationary types, they are independent of the tool number of the robot. Furthermore, there will be no problem even when an arbitrary tool number “4” is set for them.

(Cautions for setting Stud-gun) Set the gun type as “Stud” only if the tool attached on the robot R1 axis is Stud-gun. It should be selected as “Eq” if spot welding is being executed with a stationary stud-gun.

Set a gun type corresponding to the gun number as in the screen above, according to the system specifications discussed in this manual.

◆【References】◆

l If no gun number that corresponds to the tool number is set, the specific tool number will be used for other purpose.

l When setting the gun type as servo-gun, the additional axis number corresponding to the gun number will be matched in the following way.

Gun number | Gun usage | Additional axis number |

G1, G2 | Welding gun change, including servo-gun | Additional axis 1 |

G5 | Stationary Servo-gun 1 | Additional axis 2 |

G6 | Stationary Servo-gun 2 | Additional axis 3 |