8. HRSafeSpace - Practice

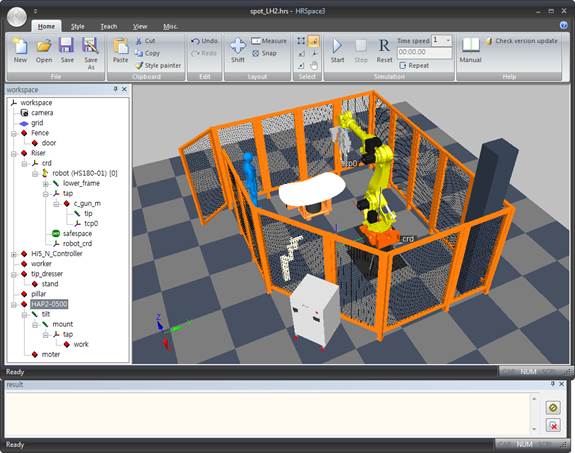

Let’s suppose we have designed a layout of robot spot-welding cell like below;

Figure 8.1 Example of robot spot-welding cell

There is one HS180-01 manipulator on a riser. A C-type spot welding gun is mounted on the robot flange, and the robot is mounted on a riser which height is 800mm. At the beginning of each work-cycle, a human worker installs a welding-workpiece on the positioner in front of the robot. The whole cell is surrounded by five-sided fence. Let’s assume the robot’s movement of Z-axis is limited to 0 ~ 3400mm because of ducts on ceiling, and there is a pillar inside of the fence.

We will configure the SafeSpace parameter by help of HRSpace visualization and then download the created ROBOT.SFS file into actual Hi5a robot controller.