2.4. Sealer Operation Property Settings

2.4. Sealer Operation Property Settings

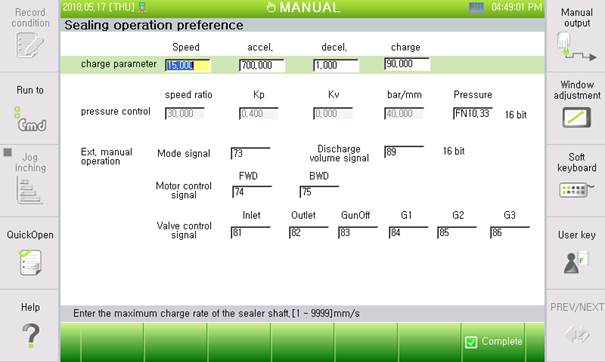

Filling, operation property of pressurization adjustment, and external manual operation parameters can be set for the sealer operation property settings. “[F2]: System” → “4: Application parameter” → “20: Sealing settings” → “<F2> Operation property”

(1) Filling parameter

Specify the filling speed and the acceleration/deceleration of the motor for the filling sealer. An excessively fast filling will cause an error of unreached minimum pressure.

Specify the ratio of filling to the total booster capacity for the filling ratio. If the primary pump pressure to the booster is higher than the atmospheric pressure setting, the cylinder will retract when adjusting the atmospheric pressure after filling. Thus, it is recommended to set the filling ratio under 100%.

(2) Pressurization control

Enter the cylinder speed control ratio and the control parameter for pressurization control.

Only skilled engineers will be allowed to adjust it if required.

Allocate a signal to output the measured pressure of the pressure sensor externally for the pressure output signal. The pressure is outputted in an integer-type, 16-bit data that multiplies measured pressure with 100.Thus, the measured pressure should be converted by dividing it with 100 on signal-receiving equipment.

(3) External manual operation

Specify the control signal to be received when manually controlling the sealing booster externally on a process control panel. With the mode selection signal input, the external manual operation mode will work. The input/output valve and gun valve are open/closed based on the external input signal on the external manual operation mode. The discharge amount selection signal is composed of 16-bit data from the specified input port; thus, the discharge amount can be received in cc. With the specified discharge amount and cylinder advance signal input, it discharges a specified amount and then stops. However, the cylinder will move forward or backward only if the valve open/close state meets requirements. For instance, it will move backward if the input valve is open while the output valve is closed. To move the booster motor through external manual operation, the controller must have a motor on in the remote mode.