2.3. Sealer Pressure Sensor Tuning

2.3. Sealer Pressure Sensor Tuning

The sealer pressure sensor tuning has different settings to receive data, which is measured with a pressure sensor of the gun booster on the robot controller. For the pressure sensor settings, press the “<F1>” key in the sealing settings menu to move to the pressure sensor-setting screen.

“[F2]: System” → “4: Application parameter” → “20: Sealing settings” → “<F1> Pressure sensor settings”

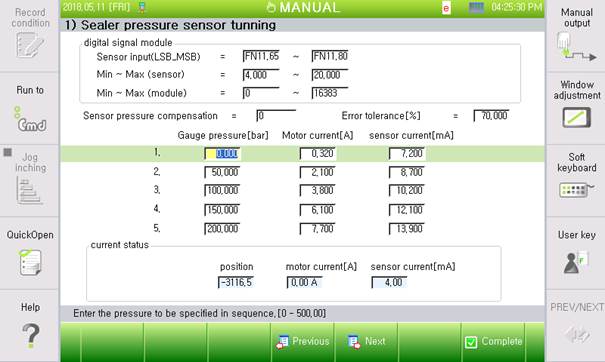

Figure 2.3 Sealer pressure sensor tuning

(1) Digital signal input module

Set a port to receive the digital data signal of the measurement of the pressure sensor for the sensor input. Enter the minimum and maximum current values of the analog signal for those of the sensor. Specify the minimum and maximum values of the digital conversion module for those of the module. Convert the received data of the digital module into current values on the basis of setting values to display the sensor current values on the current state window in real time.

(2) Sensor pressure compensation

Sensor pressure compensation can be set if there is a certain error with pressure measured with the pressure sensor.

(3) Allowed failure detection range

If the error of an estimated pressure based on a sensor-measured pressure and motor current is the same or is higher than a specified value in the allowed failure detection range, the failure can be detected with the error.

If it is set to “0,” the values will not be compared.

(4) Pressurization table

This is a table to define the relations among the pressure in the booster, motor current at the pressure, and output current of the pressure sensor. Set the gauge pressure in a manner that the pressure for tuning the pressure sensor is gradually increased. Enter the motor current value of the specified gauge pressure state for the command current. Enter the sensor current value of the corresponding gauge pressure of the sensor current.

Jog the sealer axis in a “<+/->”direction with the “<SHIFT>” key pressed to change the cylinder pressure. Adjust the pressure to reach the gauge pressure to set by pressing the jog key, and then enter the motor current and sensor current values in the pressurization table on the current state window.

The sensor pressure will be measured within the specified pressure range for the gauge pressure. Thus, allow tuning up to a high pressure in the good range for the equipment if possible.

(5) Current state

The current values of the sealer axis position, motor current, sensor current, and more are displayed in real time.