3.4. JOB program writting

3.4. JOB program writting

In order to execute the work scenario, the user should write the JOB programs, in addition to carrying out the setting for laser welding. However, since the basic contents are already written, the user just needs to refer to them and modify only the parts that need to be changed for a specific work (especially the signal address and the teaching parts). Program configuration is largely divided into OTF and STATIC modes. Each JOB program has its own purpose and is configured in a way that the programs can be called starting with main() to perform the entire welding work. The configuration may be changed for improving the performance and processing errors.

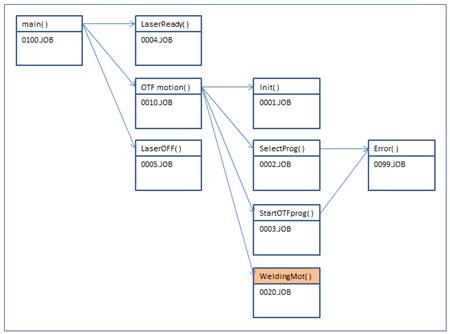

(1) OTF welding mode

The following JOB program numbers are the ones currently written. The user can add or modify programs. However, when it comes to the new work panel, the user only needs to modify the teaching part about WeldingMot(). The relevant program is used not only for storing recording files but also for driving the robot for the actual welding motion. Therefore, if the program is executed separately first to store the recording file, it can also be called when the welding is performed by executing the 0100.JOB file.

Figure 8 Overview of JOB program in OTF mode

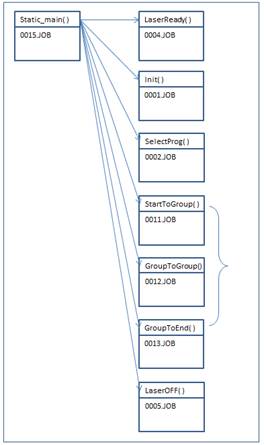

(2) STATIC welding mode

For the STATIC mode, the three programs marked in the following figure will be added. The user only needs to modify the robot position in the file.

Figure 9 Overview of JOB program in STATIC OTF mode