1.5. Job Program Teaching Using the LVS Function

1.5. Job Program Teaching Using the LVS Function

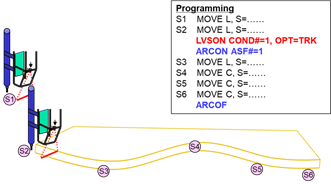

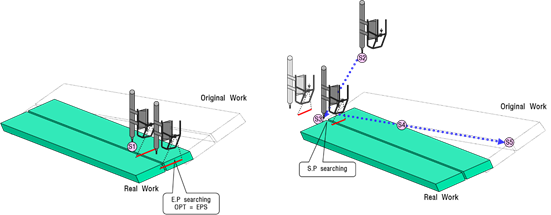

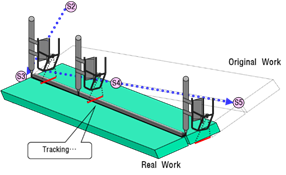

Figure 1.10 Job program teaching using the LVS function

The LVSON command should always be recorded above the ARCON command, as shown above. The reason is to start the welding with the starting point after the starting point search is completed.

When teaching is performed for the welding lines for multiple steps, and then the ARCOF command is encountered, the LVS tracking function will end. In this process, if the end point search option is used, welding will be performed while movement to the end point is taking place. Then, the arc end condition will be executed. Caution must be observed in the case of end point search. The end point can be corrected as much as the gap between the laser strip and TCP in the taught trajectory (Figure 1.8).

In addition, if the seam continues to be recognized near the end point, there is a risk of welding being performed for what is not a welding line.

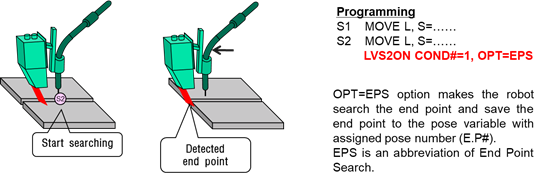

An easy solution for the problem above is to use an EPS option that is LVSON COND#=1, OPT=EPS.

If the function is used in this way, the end point can be detected and stored in the pose variable. In this process, the search distance and number of the pose variable can be set in dist and E.P# in QuickOpen.

The OPT=EPS methodology mentioned above plays the same role as wire touch sensing. In this method, the end point pose is calculated in advance and is then used to designate the specific pose, such as MOVE L, P11, S=50 mm/min, A=3, and T=1 to perform teaching.

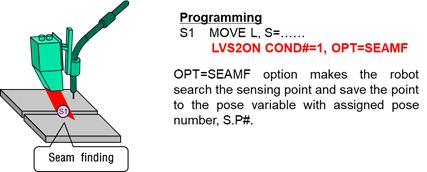

If the OPT=SEAMF method is used, the sensed point can be stored in the pose variable.

Programming Example 1

Robot programming for storing the sensing pose by using the seam finding function

S1 MOVE L, S=20%, A=0, T=0 ‘Move to the position to carry out Seam Finding. DELAY 0.2 ‘0.2 sec delay LVS2ON LVS#=1, OPT=SEAMF ‘Perform Seam Finding (Sensing pose is to be stored in S.P#). END |

Programming Example 2

Robot programming using the starting point search and end point search

In the LVS condition edit window, set both the starting point search and end point search as “enable,” and then input the search distance.

S1 MOVE L, S=20%, A=0, T=0 S2 MOVE L, S=20%, A=0, T=0 ‘Move to the starting point search position. DELAY 0.3 LVSON COND#=1, OPT=TRK ‘After the starting point search, move to the starting point, and then start tracking. ARCON ASF#=1 S3 MOVE L, S=80cm/min, A=3, T=0 ‘Welding trajectory point 1 S4 MOVE L, S=80cm/min, A=3, T=0 ‘Welding trajectory point 2 ARCOF ‘Move to the sensed end point, and then perform welding. END |

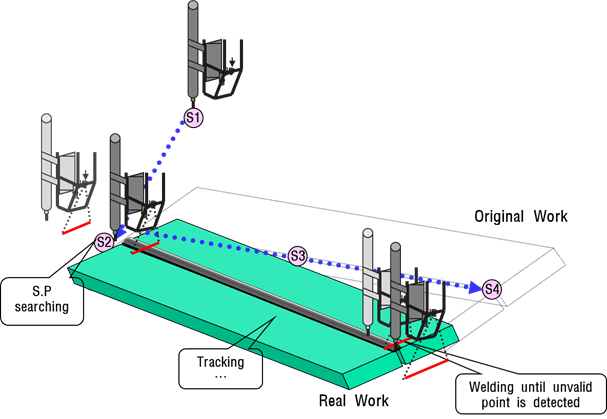

Programming Example 3

Robot programming using the starting point priority search and end point priority search

In the LVS condition edit window, set the starting point search as “enable,” set the end point search as “disable,” and then input the search distance.

Work progress 1 (Store the pose after the end point priority search.) Work progress 2 (Search the starting point.)

Work progress 3 (Perform welding up to the end point, and then end the welding.)’

S1 MOVE L, S=80cm/min, A=3, T=0 ‘Near the area where welding ends, near S4 DELAY 0.3 LVS2ON COND#=1, OPT=EPS ‘After the end point search, set E.P#=100 in the LVS condition, and store it in P100. S2 MOVE L, S=20%, A=0, T=0 S3 MOVE L, S=20%, A=0, T=0 ‘Move to the starting point search position. LVS2ON COND#=1, OPT=TRK ‘After the starting point search, move to the starting point, and then start tracking. ARCON ASF#=1 S4 MOVE L, S=80cm/min, A=3, T=0 ‘Welding trajectory point 1 S5 MOVE L, P100, S=80cm/min, A=3, T=0 ‘Welding trajectory point 2 ARCOF END |

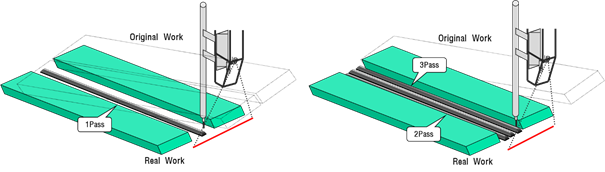

Programming Example 4

Robot programming using the LVS multipass function

Only for 1pass welding, the tracking should be enabled, while tracking should be disabled for use.

MOVE L, … ‘move to SP search position DELAY 0.3 LVSON COND#=1, OPT=TRK_TRJSAVE,S=10,RN=V100%,TCRDSFT=0,10,0 ‘1PASS, tracking with tracking to ‘VALID’ and multipass trj will be saved in P[10]~ P1[0+V100%] ARCON ASF#=1 MOVE L, ….. ‘1PASS welding ARCOF MOVE P10,… ‘Move to 2PASS multipass start position DELAY 0.3 LVSON COND#=1, OPT=TRK_TRJSAVE,S=1000,RN=V101%,TCRDSFT=0,-20,0 ‘2PASS, and save 3PASS with tracking to ‘INVALID’, multipass trj will be saved in P[1000]~ P1[1000+V101%] ARCON ASF#=1 FOR V50%=10 TO 10+V100% STEP 1 MOVE L,P[V50%], … ‘2PASS welding NEXT ARCOF MOVE P10,… ‘Move to 3PASS multipass start position ARCON ASF#=1 FOR V50%=1000 TO 1000+V101% STEP 1 ‘3PASS welding MOVE L,P[V50%], … NEXT ARCOF |