1.1. About the LVS Welding Line Tracking Function

1.1. About the LVS Welding Line Tracking Function

LVS is the abbreviation of laser vision sensor. The LVS function is used to track the welding line by automatically correcting the position and misalignment errors of the workpiece during welding. The sensors currently supported by Hi5a are the Oxford OSL, Renue, and Riftek RF627 sensors.

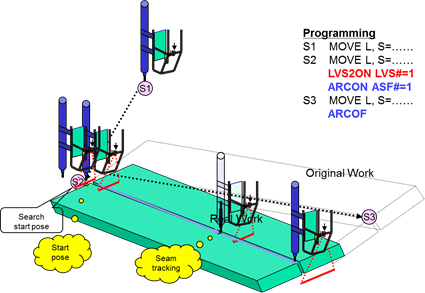

The LVS function makes it possible to perform welding along the actual workpiece welding line when the taught trajectory does not match because of the misaligned workpiece, as shown in Figure 1.1. Therefore, the taught job program may be used as is without changing it.

Figure 1.1 Example of the LVS welding line tracking in which the starting point search is used

Figure 1.1 shows an example of the LVS welding line tracking in which the starting point search is used. When the starting point search is performed, movement will occur in the direction of + Tool X to identify an invalid welding line. When an invalid welding line is found, movement to the starting point will automatically occur, saving the correction amount.

* Caution: The LVS2ON command should exist above the ARCON command. The ARCOF command should exist after one or more MOVE statements.