2.19. ARC_COND

2.19. ARC_COND

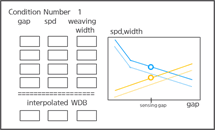

Description | The ARC_COND statement is a command to set the current, voltage, speed, weaving width, and weaving frequency for arc welding. The user can also change the condition, linearly ranging from the current ARC_COND condition to the next ARC_COND condition. In other words, the interpolation conditions will be applied in consideration of the left direction distance / right direction distance (gap), and the welding speed and weaving width will be automatically calculated based on the gap. The parameters to be set by this command can be individually designated and set by reading the desired welding condition database and designating the WDB number. | ||

Grammar | • ARC_COND <Welding condition change method>, <Welding speed>, <Left direction distance>, <Right direction distance>, <Weaving frequency>, <Current>, <Voltage> • ARC_COND <Welding condition change method>, WDB#=<Welding condition database> | ||

Parameter | Welding condition change method | Work program number where the station calibration is being taught | 1 ~ 9999 |

Welding speed | Designates the robot movement speed in the welding section; The speed in the MOVE statement ignored

| 0.6~1000 cm/min | |

Left direction distance / right direction distance | Sets the amplitude of the left/right direction for the weaving operation

| 0.0~50.0 mm | |

Weaving frequency | Sets the weaving frequency

| 0.0~10.0 Hz | |

Current | Sets the welding current for the welding section | 1~1000 A(%, m/min) | |

Voltage | Sets the welding voltage (compensation) for the welding section | -200~200 V(%) | |

Welding condition database | Sets the welding condition database number to be used in the welding section

| 1~1000 | |

Example of usage | • ARC_COND L, 30, 4, 4, 3, 400, 28 • ARC_COND L, WDB#=1 • Interpolation condition editing window

If four points are set as the interpolation conditions as above, it will be possible to change the weaving width and welding speed by performing linear interpolating variably according to the sensed gap, instead of the set left and right weaving widths. In the figure, the circles represent the welding speed and width interpolated for the reference conditions expressed in dotted lines with regard to the current gap. | ||