1.3.3.1. Operation

1.3.3.1. Operation

Press the [F7: change I, V in arc welding] key while performing arc welding in auto mode.

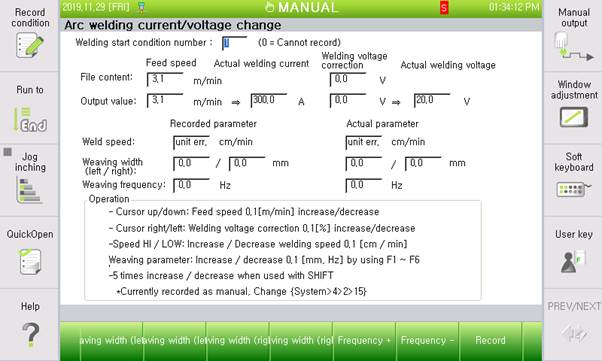

Figure 1.10 Arc welding current/voltage change dialog box(EWM)

The figure above shows a dialog box that will be displayed when EWM welder is used. The form of the dialog box can be differently displayed depending on the welder. The individual options of the dialog box are as below.

(1) Feed speed

① File content: Displays the feed speed of the welding condition that is currently being used.

② Output value: Displays the feed speed that the controller outputs to the welder currently

(2) Actual welding current

① Output value: Displays the output welding current that is being transmitted from the digital welder to the controller.

(3) Welding voltage offset

① File content: Displays the relevant welding voltage compensation of the welding condition currently being used

② Output value: Displays the welding voltage compensation that the controller currently outputs to the welder

(4) Actual welding current

① Output value: Displays the output welding voltage that is being transmitted from the digital welder to the controller.

(5) Recorded parameters

① Displays the recorded parameter of the work program that the robot is currently performing; the values will not be changed, even when the keys are operated.

(6) Actual parameters

① Displays the speed and weaving parameters with which the robot actually performs; the values can be changed by operating the keys.

l The change in the current/voltage will be saved in the welding start condition and not in the end condition.

l Of the ARCON command type commands, the commands for which separate current and voltage values are designated, changes will be saved in the welding condition.

Ex.) ARCON C=200,V=20,ASF#=1 <- The changed current and voltage values will be saved in #1 of the welding start condition.