3.2. Encoder resolution auto setting

3.2. Encoder resolution auto setting

Encoder resolution can be defined by the count of pulses that will be generated when a linear type conveyor (press) moves 1m or when a circular type conveyor (press) turns 1 degree.

In order to calculate the encoder resolution automatically, it is needed to push the [F2: Resolution calculation] key on the setting screen of “『[F2]: System』 → [4: Application Parameter] → [4: Sensor Synchronization] → [3: Synchronization Parameter]”.

(1) As shown below, after a workpiece passes through the limit switch, the conveyor will stop.

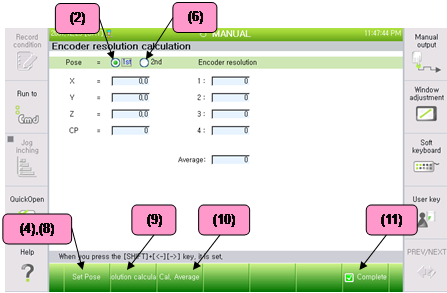

(2) Select the position as <1st>.

(3) Move the end part of the robotic tool to a specific position on the workpiece.

(4) Push the [F1: Set Pose] key to record the current position of the robot as well as the encoder pulse value.

(5) Move the workpiece by running the sensor as shown below (1m or longer).

(6) Select the position as <2nd>.

(7) Move the tip of the robotic tool to the specific position designated at Step (3).

(8) Push the [F1: Set Pose] key to record the current position of the robot as well as the encoder pulse value.

(9) Push the [F2: Resolution calculation] key to calculate the encoder resolution and record the value in the encoder resolution section. Repeat the steps of (1) ~ (9) to calculate the resolution of totally 4 encoders.

(10) Push the [F3: Cal. Average] key to calculate the average of the recorded resolution values of encoders.

(11) Push the [F7: Complete] key to set the average value as the encoder resolution.