6.4. TCP and tool number

6.4. TCP and tool number

As the child model of airless_gun, there will be a coordinate system model called tcp (Tool Center Point). The relative location/direction data of tcp based on the tap is used as the location/direction data of tool no. 0 (T0) when recording the step or running the simulation. Hi5 controller supports a total of 16 tools (T0~T15), and the coordinate models are tcp0~tcp15.

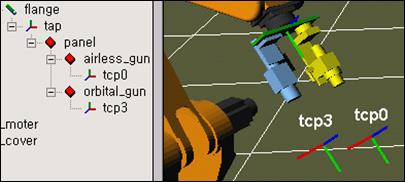

For example, let’s assume that 2 tools are attached as follows and names set to tcp0 and tcp3.

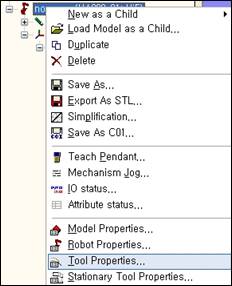

If you want to directly edit the tool data, right click on the robot and open the pop up menu to select tool properties.

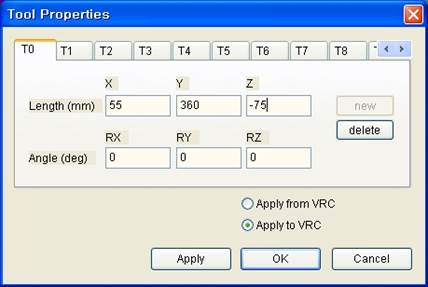

The tool properties window appears as follows. For example, if you want to edit the data of tcp3, click on the T3 tab and enter the accurate length and angle of the tool. Then click on OK. The entry method is the same as the setting screen of the tool parameter for the actual Hi5 controller.

(You can adjust the relative value of model properties of tcp or adjust the tool data by using the shift function.)

Choose one from options as below to select how to connect with a virtual controller.

Apply from VRC | Changes in Tool data on a virtual controller is immediately applied to the virtual controller. This is useful when you observe a 3D screen by importing onsite robot control files or utilize virtual Teach Pendant to practice the operation. |

Apply to VRC | Changes in Tools data on HRSPace3 is immediately applied to the virtual controller. This is useful when you create robot control files by designing work cells on a 3D screen. |

The set tool data can be utilized as follows.

(1) When you are jogging the tool coordinate using the mechanism jog window, it is based on the currently selected tool coordinate.

(2) When recording the step with the record button of T/P, you can create the step on the location of the currently selected tool coordinate.