3.2. Conveyor constant auto setting

3.2. Conveyor constant auto setting

Conveyor constant refers to the number of pulses generated when the conveyor moves 1m for the linear type and 1deg for the circular type.

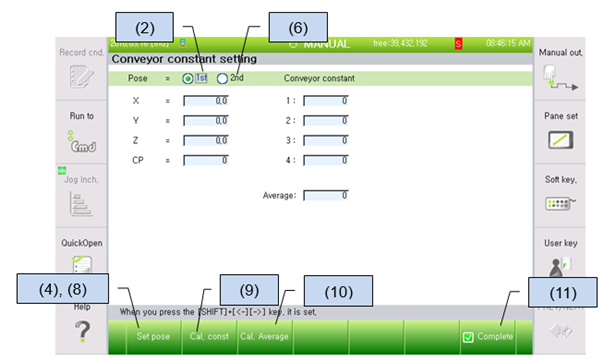

To automatically calculate the conveyor constant, click on 『[F2]: System』 → 『4: Application parameter』 → 『4: Conveyor synchronization』 → 『2: 1st parameter』 and then 『[F2]: Cnst set』.

(1) After the workpiece passes the limit switch as shown below, the conveyor stops.

(2) Select <1st> as location.

(3) Move the tool end of the robot to the specific location of the workpiece on the conveyor.

(4) When you press 『[F1]: Set pose』, the conveyor pulse value will be recorded with the current location of the robot.

(5) Operate the conveyor to move the workpiece as shown below. (1m or above)

(6) Select <2nd> as location.

(7) Move the tool end of the robot to the specific location designated in (3).

(8) When you press 『[F1]: Set pose』, the conveyor pulse value will be recorded with the current location of the robot.

(9) When you press 『[F2]: Cal. const』, the conveyor constant will be calculated and recorded in the conveyor constant item.

When you repeat the process of (1) ~ (9), you can calculate total of 4 conveyor constants.

(10) When you press 『[F3]: Cal. Average』, the average of the recorded conveyor constants will be calculated.

(11) When you press『[F7]: Complete』, the average value will be registered as the conveyor constant.