5.1.5. B-AxisReducer

5.1.5. B-AxisReducer

Attention

Do not inject excessive grease. The excessive grease would cause an abnormal operation. |

n Grease Replacement

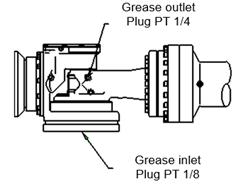

(1) Prepare a grease nipple A-PT1/8 and then make the R2-Axis 0°degree.

(2) Remove the grease inlet plug and install grease nipple A-PT1/8.

(3) Make the R2-Axis -90°degree and then remove the grease outlet plug.

(4) Inject the grease into the grease inlet using a grease gun.

ü Grease type : VIGO GREASE RE0 ü Amount of grease : 950cc |

(5) The grease replacement is complete when new grease appears in the outlet port. The new grease can be distinguished from the old one by color.

(6) Discharge excessively fueled grease and residual pressure. (Refer to the discharge procedure below.)

(7) Clean the greased around the outlet and assemble the seal-taped plug into its original state.

n Procedure in discharging excessively fueled grease and residual pressure after grease replacement and injection

(1) Attach a grease receiver or a hose to the grease outlet to prevent contamination from discharged grease.

(2) Operate it within a range without surrounding and interference under the following conditions.

① Operation angle : 120° or more

② Operation speed : 100%

③ Operation time: 20 minutes or more

(3) Wipe the outlet port with a cloth and attach the plug.