4.6. Inspection the Timing Belt

4.6. Inspection the Timing Belt

The timing belt is used for HS165D high density robot in the axis V drive part. If the drive part of timing belt has vibration/noise after every 1500 hours, check the belt tension. In case of inadequate belt tension, it could have a serious bad influence on the performance of robot.

n How to check the belt tension

① Turn the power off.

② Take off the A2-arm Cover.

③ Figure out the mean by measuring the tension more than 3 times with the sonic tension meter.

④ Compare the computed mean with the adequate belt tension.

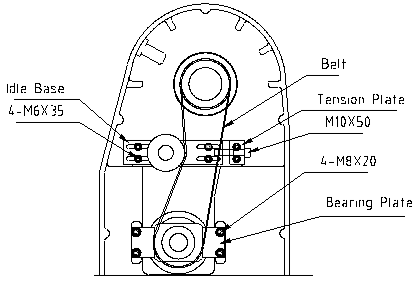

⑤ If it does not agree with the adequate tension, loosen the 4-M6X35 bolt of Idle Base, indicated in [Figure 4.4], and adjust the tension by turning the M10X50 of Tension Plate.

⑥ After adjusting the tension, fasten the 4-M6X35 bolt of Idle Base tight. (adequate tension 400N±10%)

⑦ Lay the A2-Arm Cover.

⑧ Turn the power on.

n How to replace the belt

① Turn the power off.

② Fix the Axis by inserting the fixing bolt into the pin hole in the Axis V. ( preventing the ARM dropping)

③ Take off the A2-arm Cover.

④ Loosen the 4-M6X35 bolt of Idle Base, indicated in [Figure 4.4], and completely eliminate the belt tension of Tension plate by turning the M10X50 bolt.

⑤ Disassemble the bearing housing connected to the motor axis of Axis V.

⑥ Remove the belt and replace it with a new one.

⑦ Adjust the tension, in the same manner of the above belt tension checkup, and assemble it in the reverse order of disassembly.

Figure 4.4 Checkup part for timing belt tension in Axis V