7.3.8.1. Setting of model-based collision detection

7.3.8.1. Setting of model-based collision detection

The model-based collision detection function enables the detection of a collision by calculating the difference between the torque the robot should normally generate during operation and the torque actually measured, based on the robot’s dynamic model. It is possible to adjust the responsiveness to collision by setting the sensitivity and detect any external contact that may occur when the robot moves at a low speed. In addition, adjusting the sensitivity of the collision detection for each operation section using a command is also possible.

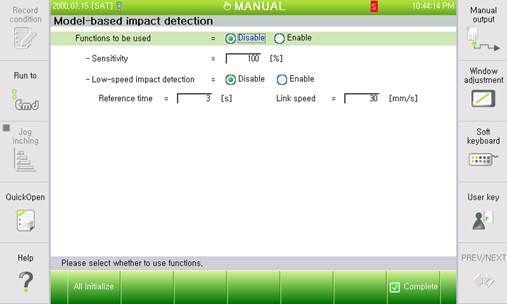

Figure 7.70 Screen for setting the collision detection (for each axis)

n Use of function: Sets whether to use the collision detection function

n Sensitivity: Sets the sensitivity of collision detection. The larger the value, the more sensitively responsiveness to the impact occurs (0%–200%)

It is possible to adjust the sensitivity for each section using the command ColDet Sensitivity in the job program. However, the sensitivity set using the command will be initialized to the sensitivity set in the menu of this function when the main program is ended or the step counter is reset.

Example of use of the command

Input of the command: “[F6]: Command inputting”→”[F1]: Motion, I/O” → “ColSense”

If the sensitivity is set to 100% in the collision detection menu

- S1–S4: Detection occurs at 100% sensitivity.

- CALL 10–S7: Detection occurs at 50% sensitivity.

n Low-speed collision detection

① Use of function: Sets whether to use the low-speed collision detection function that applies to a collision with a low impact force

② Reference time: Reference time for determining a collision. If an impact force is applied for longer than the reference time, it will be identified as a collision.

③ Link speed: Reference speed for determining a low speed

Low-speed collision detection will occur only at a speed below the link speed.

The following menus can be displayed and edited only in Engineer mode or above.

n Detection reference for each axis: This refers to the allowable ratio of the low-speed collision torque error. The lower it is, the more sensitively responsiveness to a low-speed collision occurs.

n To: This is a time constant for detecting sudden changes in the torque caused by a collision. The lower the value, the more sensitively responsiveness to the collision occurs.

l Because this function enables the detection of a collision on the robot axis, collision detection will not occur if the impact cannot be transmitted to the robot.

l This function only enables the detection of a collision on the robot when the motor is on.

l Some special custom robots do not support this function.

l Collision will not be detected when any of the load estimation and sensor-based/sensorless force control functions are activated.

l If the tool weight and additional weight for each axis are different from the actual values, false detection may occur.

l This function is supported by a Hi5a controller of version V40.17-00 or higher.