2.4. Step 2.Application setting

2.4. Step 2.Application setting

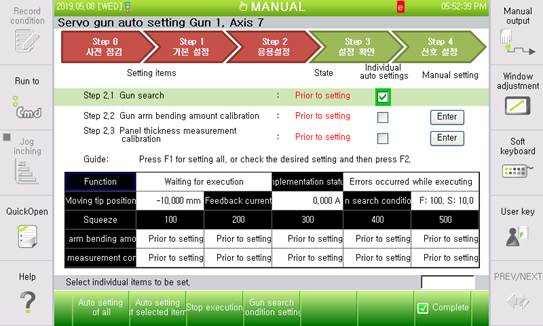

Once basic setting is complete, application setting can be performed. Application setting can be performed after the “squeeze force – current table tuning” process. In the application setting, the gun search reference location is determined, the servo gun arm bending at the time of squeeze is estimated, and the compensation procedure for accurately measuring the panel thickness is performed.

Application setting consists of the following three items.

(1) Gun search

- Set the reference location for measuring the tip consumption, and check the consumption once.

- For manual setting, refer to the “Gun search” chapter.

(2) Gun arm bending compensation

- The gun arm bending compensation needs to be set in a way to compensate the degree at which the gun arm is bent when servo gun squeeze is performed. It is required to set the bending according to the squeeze force set in the squeeze force – current table.

- For manual setting, press the manual setting button in the figure above, or select the gun number you want to set in『[F2]: System』 → 『4: Application parameter』 → 『1: Spot welding』 → 『3: Welding gun parameter』, and then, press 『[F6]: Application condition』 for entry.

(3) Panel thickness measurement compensation

- The panel thickness measurement compensation is a setting to improve the precision of the panel thickness measured with the ThickCheck command.

- For manual setting, press the manual setting button in the figure above, or select the gun number you want to set in『[F2]: System』 → 『4: Application parameter』 → 『1: Spot welding』 → 『3: Welding gun parameter』, and then, press 『[F6]: Application condition』 for entry.

The “Gun search” setting in the application setting is compulsory. If “Gun search” is not set, it is impossible to execute and teach spot welding–related commands (e.g., SPOT GN = 1,...).

On the other hand, the “Gun arm bending compensation” and “Panel thickness measurement compensation” are independent of the execution and teaching of spot welding–related commands but are necessary settings for accurate operation and panel thickness measurement.

The basic setting can be carried out both in the autosetting and manual setting modes.

(1) Autosetting

- The servo gun automatically moves and executes “Gun search,” “Gun arm bending compensation,” and “Panel thickness measurement compensation.” All items in the application setting can be automatically set.

(2) Manual setting

- The user performs “Gun search” and inputs the values for “Gun arm bending compensation” and “Panel thickness measurement compensation.”