1.2. Mechanism of Sealer Aplication

1.2. Mechanism of Sealer Aplication

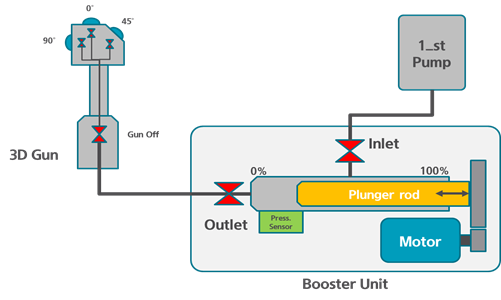

Figure 1.3 Sealing system with a 3-D gun

The configuration of the sealing system depends on site conditions or equipment. For instance, a gun can be an integrated type consisting of a gun and a booster unit, but a 3-D gun can be applied to configure the system as shown above. However, the basic system consists of a primary pump, a booster unit, and a gun.

This function enables the robot controller to control the opening/closing of valves and the pressurization for the booster unit and gun. For example, the cylinder is filled with a sealing solution from the primary pump by retracting the cylinder with only the input valve open for filling. If the cylinder reaches the filling-complete position, it waits until the filling-complete pressure is reached when the sealing solution fills the cylinder, and then closes the input valve; opens the output valve; and adjusts the position of the cylinder to reach the atmospheric pressure.

When applying the sealer, the sealing solution is applied onto a workpiece by opening the gun-off valve and specified gun valve and then pushing the cylinder. If the discharged flow cannot reach the target with the advancing speed of the cylinder as soon as the valve opens, a set pressure is applied before discharging so that the application amount can be adjusted at the beginning of discharge. Here is an example of an application shape at the beginning of discharge based on the initial pressure. Set adequate advance pressurization based on the state of the starting point of the bead after a test application.