3.4. Output assignment signal

3.4. Output assignment signal

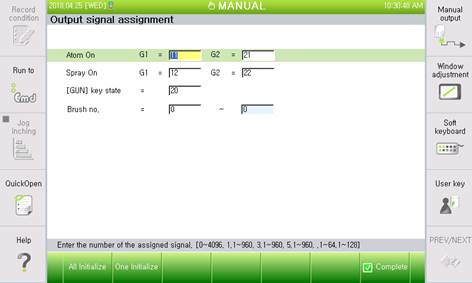

1) The Hyundai robot controller provides four output assignment signals relating to the painting application.

§ Atom On/Off: Output signal for controlling air pressure in supplying paint

§ Spray On/Off: Output signal for controlling paint valve

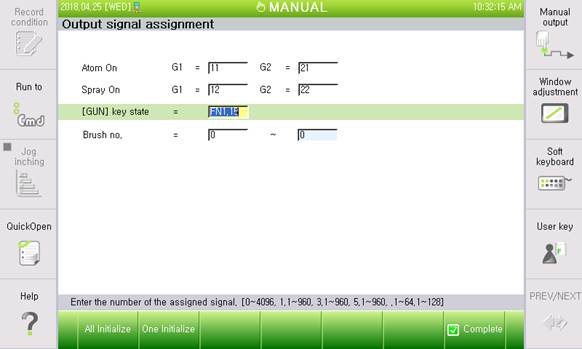

§ [GUN] key state: Output signal for indicating on/off state of the [GUN] key on the teach pendant

§ Brush number : Signal outputting the selected brush number with the SELBRUSH command

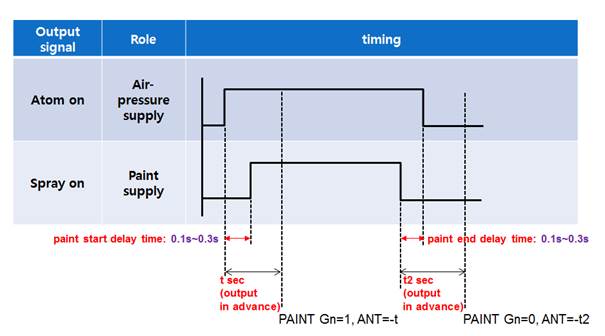

2) Atom On and Spray On directly affect the painting quality. Atom On refers to the supply of the atomizer air that atomizes paint and forms paint patterns, while Spray On refers to the opening of the solenoid valve for paint spray. Between these two signals, timing adjustment is needed for ensuring painting quality, and these signals are sent in the sequence shown in Figure 3.3 according to the on/off state of the PAINT command.

Figure 3.3 Atom/Spray output signal timing for the on/off switch of the PAINT command

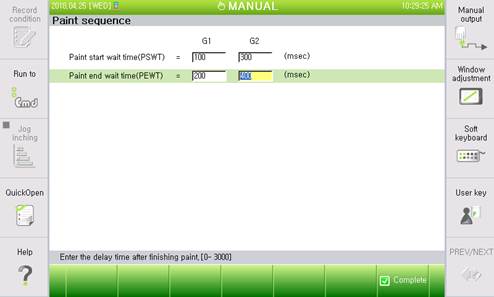

3) In timing the Atom/Spray signal, the sequence should first supply air pressure because a constant pressure should be supplied for normal paint supply. The timing should be adjusted at the site in consideration of the time lag caused by the electric solenoid valve and the hose length. You can set the timing sequence in “[F2: System]” → “4: Application Parameter” → “13: Painting” → “1: Painting Sequence” window (Figure 3.4). Carefully set the timing sequence because the adjustment of the timing for supplying or shutting off paint may either improve or degrade the quality.

Figure 3.4 Atom/Spray (painting sequence) output signal-timing dialog box

4) The GUN key state signal is an output signal indicating that the Atom and Spray output signals can be controlled by the PAINT command. This key can be activated in the automatic mode by the [GUN] key of the teach pendant. This key can also be controlled by an external input signal. If control is transferred to the outside, it cannot be activated by the [GUN] key of the teach pendant. (See 3.3 “Input Assignment Signal”.)

5) You can set each output assignment signal in “[F2: System]” → “4: Application Parameter” → “13: Painting” → “2: Output Signal Assignment” dialog box (Figure 3.5).

Figure3.5 Painting application output signal-assignment dialog box

6) When the operation has been stopped and restarted in the painting section where the PAINT command is on, the Atom/Spray output signals of the gun are switched on (activated) or off (deactivated) to meet the sequence timing. When operation is stopped, the Spray output signal is switched off first, and the Atom output signal is switched off after the sequence timing. When operation is restarted, the Atom output signal is switched on first, and the Spray output signal is switched on after the sequence timing.

7) When the SELBRUSH command is executed, the brush number set as an argument is output as the 8-bit signal set in the Brush number

8) In assigning output signals, when no user DI0 board or field bus is available, you may use the TBI0 port of the BD530 system bus as shown in Figure 10. The TBI0 connector has four hardwired output signal ports. Among them, as Ports 1 and 3 are used for other application purposes, Ports 2 and 4 may be used for Atom output (Port 2 - D04098) and Spray output (Port 4 - D04100) for the painting application. (Ports 1 through 4 are mapped to D04097 through D04100.)

Figure 3.6 BD530 system board

9) AS shown in Figure 3.7, you may assign the desired output signals by the field bus communications.

Figure 3.7 Example of assigning field-bus output signals