7.2. Arc welding data autosaving

7.2. Arc welding data autosaving

This function is used to automatically save the arc welding data in text files. It is a useful function to manage the history of the arc welding works and relevant past data. In order to activate the function, it is necessary to set “Enable” in 『[F2: System]』 → 『4: Application parameter』 → 『2: Arc welding』 →『18: Saving welding data during the welding』

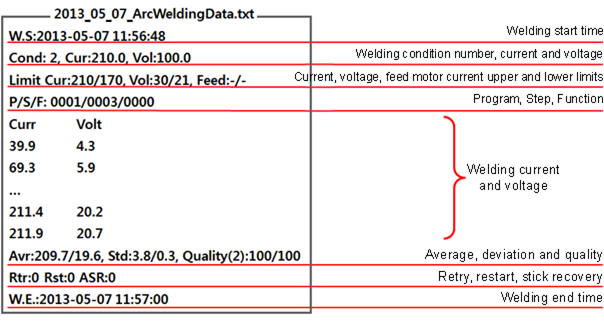

The data related to the current/voltage sent from the welder and additional data, including welding start time, end time, and condition along with statistical data, such as average, deviation, and quantitative data will be saved automatically. The process starting from the generation of the ARCON command to the stage of arc off will be considered as one cycle of welding. In each cycle, data will be saved in the following format. The saved statistical data will correspond to each welding cycle. The types of data are as shown below.

Figure 7.5 Saved arc welding data

One single text file containing the data will be saved into a specific folder in the teach pendant every day (ResidentFlash*bin*ArcWeldingData). The file name will be yyyy_mm_dd.ArcWeldingData.txt. If the file name is changed, it could be impossible to use the welding data check program that is provided by the manufacturer. It is recommended to maintain the basic name of the file.

Considering that there is a limit to the memory of the teach pendant, files will be deleted, starting with the oldest, automatically when there is not enough free memory left in the teach pendant. In addition, if there are some files that are old, they will be deleted automatically. Thus, it is recommended to make backup files periodically if it is necessary to keep the history of the arc welding works.

The stored welding data will exist in text form, making it difficult to locate and understand the desired data at first sight. In order to overcome such inconvenience, the manufacturer provides the following two methods to help users to easily find the desired welding data and understand the located data at first sight.

1. PC-based arc welding check program

2. Arc welding data management function (for teach pendants, refer to 7.3 Arc welding data management function)

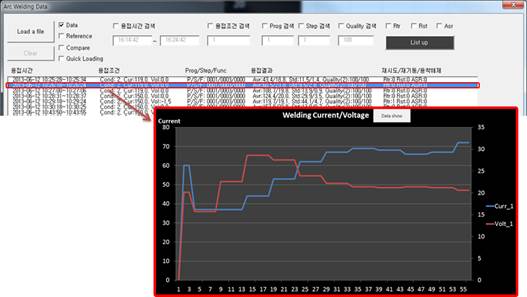

The PC-based arc welding data check program makes it possible for the user to check the backup files easily through a PC or a laptop computer. Users can search desired welding data by using the search parameters, such as welding time, welding condition, program and steps after selecting the desired welding file. In addition, the searched welding data will be visualized in graphs, allowing the users to check them intuitively. The welding data will also be compared with visual tools, making it possible to make a comparison with the past data.

Figure 7.6 PC-based arc welding data check program

In order to use the program, the manufacturer should be contacted. Refer to the last appendix of the manual for the method regarding the use of the PC-based arc welding data check program.