6.1.4. Basic pattern

6.1.4. Basic pattern

Set each element on the following pictures.

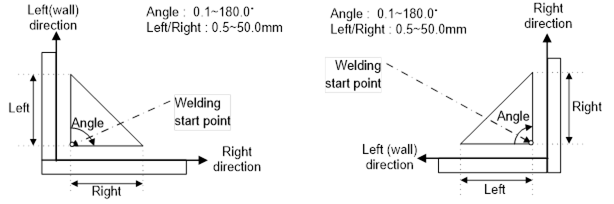

(1) Wall direction: Vertical direction (2) Wall direction: Horizontal direction

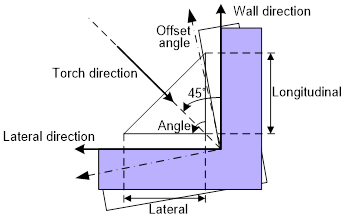

(3) Wall direction: torch position standard

Figure 6.3 Weaving elements according to the wall direction

(1) Left direction distance: Sets the distance of the left (wall) direction.

(2) Right direction distance: Sets the distance of the right direction.

(3) Angle:

Sets the left (wall) direction and right direction angles as shown in Figure 6.2. The angle indicates from the left (wall) direction to the right direction. But, this angle is ignored when using REFP 4.

(4) Wall direction (Refer to Figure 6.3)

For setting to decide whether the vertical direction (Figure (1), the horizontal direction (Figure (2) or the torch position direction (Figure (3) will be used as the left (wall) direction. In general, the vertical direction is used as the left (wall) direction, while the horizontal direction is mainly used for a 180-degree weaving work that is to be performed on a flat surface. The left (wall) direction for a weaving work that will be performed based on the torch position direction will be set to be counterclockwise based on the weaving moving direction (The moving direction in Figure (3) is outward bound direction, ⊙). In case of the weaving work based on the torch position direction, it is possible to respond to all different left (wall) directions and also respond to cases in which the left (wall) direction changes in the middle of weaving.

(5) Offset angle (Refer to Figure 6.3)

If the wall direction is set based on the torch position direction, the rotating angle for the weaving surface is to be set based on the weaving moving direction (The moving direction in Figure (3) is outward bound direction, ⊙). When 0 degree is set, the angle created between the left (wall) direction and the right direction needs to be cut in half.

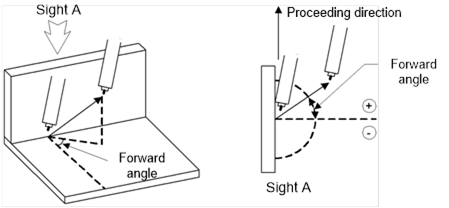

(6) Forward angle

This is the angle of the weaving oscillation direction relative to the welding line. The possible setting range is -90.0° – 90.0°.

When the angle is set to 0°, weaving will be performed at the right angle to the welding line.

Figure 6.4 Weaving forward angle

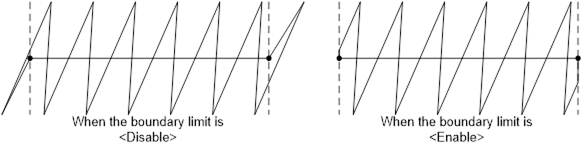

(7) Boundary limit

In case of a weaving work whose moving angle is not 0 degree, the weaving work may step over the boundary of the weaving range at the start and end sections of it. It is required to set whether to allow weaving to take place while not crossing the range boundary by restricting the boundary of the range by setting the boundary limit.