4.3. Arc sensing with the weaving width auto setting through touch sensing

4.3. Arc sensing with the weaving width auto setting through touch sensing

Create one work program that can be applied to both workpieces, as shown below:

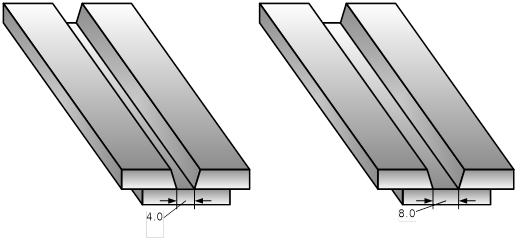

Figure4.2 Workpiece for butt touch sensing and arc sensing

The work environment will be assumed as below:

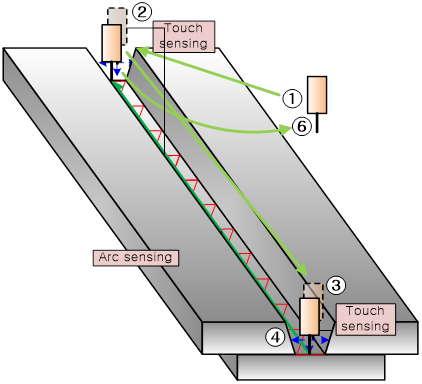

Process of welding between two workpieces

180° flat weaving

The welding progress direction is X + direction. The touch sensing of the workpiece is performed left and right in the Y direction.

It is assumed that the setting of the arc sensing parameters has been completed.

In the case of a 4.0 mm gap, the welding speed is 7.0 mm/sec.

In the case of an 8.0 mm gap, the welding speed is 3.5 mm/sec

The work sequence is as below:

1) Measure the welding center position and gap distance at the butt part of the end point using the touch sensing command.

2) Measure the welding center position and gap distance at the butt part of the start point using the touch sensing command.

3) Determine if the V10! Value is within the allowable value. Stop when it exceeds the range of 2.0–10.0 mm.

4) Designate each half of the measured distance as the distance in the wall direction (left surface) and in the opposite direction (right surface), respectively.

5) Perform interpolation calculation using the welding speed of 4.0 mm/sec and 8.0 mm/sec. If the gap is less than 4.0 mm, apply a fixed speed of 7.0mm/sec, and if the gap exceeds 8.0 mm, apply a fixed speed of 4.0 mm/sec.

6) Progress the work through the automatic entering of the weaving width and welding progress speed using the calculated value.

7) Return to the original position after the work is completed.

Figure4.3 Butt touch sensing and arc sensing

l The example program is as follows:

~~~~~~~Arc sensing program : 0002.JOB~~~~~~~~~~~~~~~

'Butt Arc sensing program

Digits in the units place: Start condition. , Digits in the tens place: End condition

S1 MOVE P,S=60%,A=3,T=1 ' 1: Operation start point

S2 MOVE L,S=30%,A=3,T=1 ' 2: End point touch sensing position

TOUCHSEN TSC#=2,+TY,-TZ,5,P10,V11! ' 3: Save the end point touch sensing position at P10

S3 MOVE L,S=30%,A=3,T=1 ' 4: Start point touch sensing position

TOUCHSEN TSC#=3,+TY,-TZ,5,P1,V1! ' 5: Save the start point touch sensing position at P1

'Calc. weld speed, width according to Gap V1! Setting of the speed according to the gap

IF V1!<2.0 OR V1!>10.0 THEN ' Exceeded the allowable range

GOTO *Error

ELSEIF V1!<4.0 THEN ' If the gap is less than 4.0 mm, fix the speed as 7.0 mm/sec

V3!=7.0 'Weld speed at start

ELSEIF V1!>8.0 THEN ' If the gap is more than 8.0 mm, fix the speed as 4.0 mm/sec

V3!=4.0 'Weld speed at start

ELSE ' If the gap is within the range of 4.0–8.0 mm, calculate the speed through linear interpolation

V3!=(7-3.5)/(4-8)*V1!+10.5 ' Linear interpolated weld speed at start

ENDIF

V4!=V1!/2.0 'left side width ' Designate the half of the gap as the left-side weaving width

V5!=V1!/2.0 'right side width ' Designate the half of the gap as the right-side weaving width.

'--------------------------------------------------------

'Calc. weld speed, width according to Gap V11!

IF V11!<2.0 OR V11!>10.0 THEN ' Exceeded the allowable range

GOTO *Error

ELSEIF V11!<4.0 THEN ' If the gap is less than 4.0 mm, fix the speed as 7.0 mm/sec

V13!=7.0 'Weld speed at start

ELSEIF V11!>8.0 THEN ' If the gap is more than 8.0 mm, fix the speed as 4.0 mm/sec

V13!=4.0 'Weld speed at start

ELSE ' If the gap is within the range of 4.0–8.0 mm, calculate the speed through linear interpolation

V13!=(7-3.5)/(4-8)*V11!+10.5 ' Linear interpolated weld speed at end

ENDIF

V14!=V11!/2.0 'left side width

V15!=V11!/2.0 'right side width

'---------------------------------------------------------

S4 MOVE L,P11,S=20%,A=3,T=1 ' 6: Move to the welding start point

WEAVON WEV#=2 ' 7: Start the weaving and arc sensing

ARCON ASF#=2 ' 8: Start the welding

ARC_COND L,V3!,V4!,V5!,2,400,32 ' 9: Start of weld parameter continuous change

S5 MOVE L,P10,S=60cm/min,A=3,T=1 '10: Move to the welding end point

ARC_COND L,V13!,V14!,V15!,2,400,32 '11: End of weld parameter continuous change

ARCOF ASF# '12: End the welding

WEAVOF '13: End the weaving and arc sensing

S6 MOVE P,S=60%,A=3,T=1 '14: Operation end point

END

*Error '15: Position for retracting when the range of gap is exceeded

DO200=1 '16: Signal output for indicating an error

STOP '17: Stop the robot

END

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~